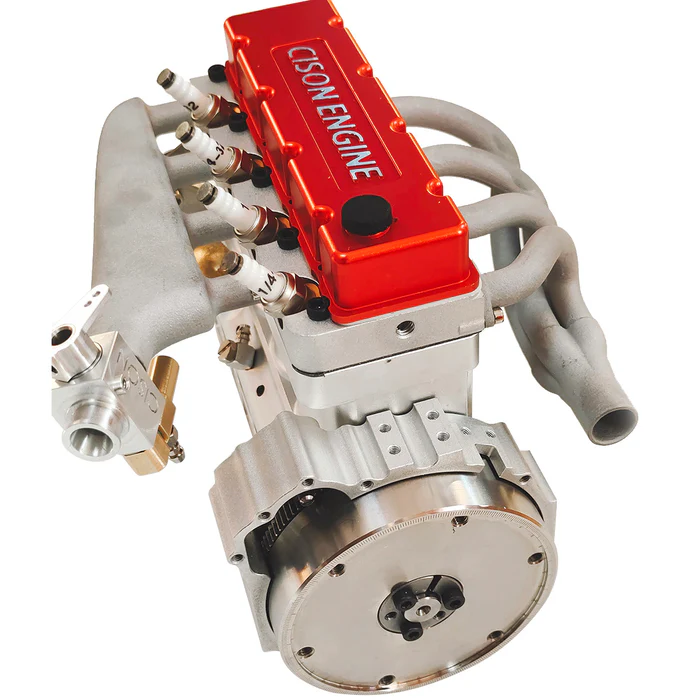

Introduction to CISON Engines

CISON (Controlled Intelligent Spark-Ignited Opposed-Piston) engines represent a groundbreaking innovation in engine technology. By blending the efficient opposed-piston architecture with advanced combustion control strategies, CISON engines offer improved performance, fuel efficiency, and reduced emissions. This article delves into the unique features of CISON engines, their advantages, and how they are shaping the future of internal combustion technology.

Key Features of CISON Engines

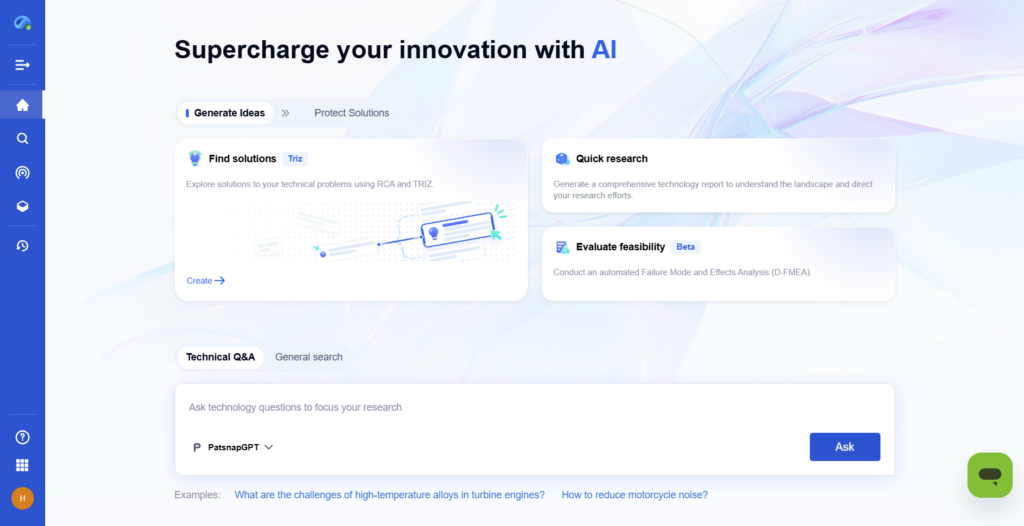

What makes CISON engines unique? Eureka Technical Q&A highlights their performance, efficiency, and durability.

Opposed-Piston Design

CISON engines use a two-stroke compression ignition system with an opposed-piston configuration. Two pistons are positioned crown-to-crown within a single cylinder bore. This design eliminates the need for traditional valve trains, as the pistons themselves act as valves for the inlet and exhaust ports. The result is a simpler and more efficient engine architecture.

Air Compression and Fuel Injection

During the compression stroke, the pistons move toward each other, compressing the air inside the cylinder. The compressed air’s temperature rises significantly. Near the top dead center (TDC) position, liquid fuel is injected at the center of the cylinder. The high temperature of the compressed air triggers autoignition of the fuel, pushing the pistons apart during the power stroke and generating power efficiently.

Improved Combustion Efficiency

CISON engines achieve exceptional combustion efficiency by injecting fuel into the air near TDC. This allows the fuel more time to vaporize and mix with the compressed air, creating a homogeneous air-fuel mixture. This design leads to more complete combustion, reducing the formation of pollutants like nitrogen oxides (NOx) and particulate matter compared to traditional compression ignition engines.

Ignition Assist for Reliability

To ensure reliable starts in cold conditions or when using low-cetane fuels, CISON engines incorporate ignition-assist devices. These can include glow plugs, spark plugs, or plasma ignition devices, which help initiate combustion until the engine reaches optimal operating temperature for autoignition.

High Compression Ratios for Efficiency

CISON engines operate with compression ratios between 15:1 and 25:1, making them highly efficient. These ratios allow the engine to combust low-cetane fuels (with cetane numbers below 30) effectively. The design ensures at least 50% of the fuel is premixed with air before ignition, further improving combustion quality and reducing emissions.

Prechamber Design for Controlled Combustion

Some CISON engines feature prechambers connected to the main combustion chambers. These prechambers include gas valves, ignition devices, and a gas-air mixture source. This setup enables controlled combustion, enhancing efficiency and lowering emissions even further.

Popular CISON Engine Models

V8 CISON Engines

V8 CISON engines combine the power of eight cylinders arranged in a “V” configuration with the advanced combustion strategies of the CISON design. These engines are ideal for:

- High-performance vehicles: Delivering exceptional power and torque for sports cars and luxury sedans.

- Heavy-duty applications: Providing robust performance for trucks and industrial machinery.

- Efficiency and emissions: Leveraging CISON technology to achieve cleaner combustion and better fuel efficiency.

V-Twin CISON Engines

V-Twin CISON engines feature two cylinders in a “V” configuration, offering a compact and lightweight design. This setup is popular in:

- Motorcycles: Delivering a balance of power and agility for high-performance and touring bikes.

- Small machinery: Powering compact equipment like generators and utility vehicles.

- Fuel efficiency: Utilizing the CISON architecture to optimize fuel consumption and reduce emissions.

Inline CISON Engines

Inline CISON engines arrange all cylinders in a straight line, offering simplicity and smooth operation. This configuration is commonly used in:

- Modular designs: Allowing easy integration into various applications due to their straightforward construction.

- Passenger vehicles: Providing reliable performance for sedans, hatchbacks, and SUVs.

- Industrial equipment: Powering machines that require steady and efficient energy output.

Applications of CISON Engines

Where are CISON engines used? Eureka Technical Q&A explores their applications in automotive, industrial, and power generation sectors.

Light and Heavy-Duty Vehicle Engines

- Passenger vehicles: Enhancing mileage and performance for everyday use.

- Trucks and buses: Delivering reliable power and better fuel efficiency for long-haul and urban transport.

Stationary Power Generation

- Backup generators: Providing dependable power during outages.

- Industrial facilities: Supporting large-scale operations with efficient energy production.

Range Extenders for Hybrid Electric Vehicles and Aircraft

- Hybrid cars: Enhancing range and reducing reliance on battery charging.

- Electric aircraft: Offering supplementary power for longer flights and more flexible operations.

Marine Engines for High Power Density

- Recreational boats: Delivering strong performance in a small footprint.

- Commercial vessels: Supporting cargo and passenger ships with reliable and efficient propulsion.

How to Choose the Right CISON Engine for Your Needs

Power Output and Performance

Evaluate the power requirements of your application.

- Horsepower and torque: Ensure the engine delivers sufficient performance for your needs.

- Efficiency: Look for engines with high fuel efficiency to reduce operational costs.

- Emission Standards: Ensure compliance with applicable environmental regulations.

Size and Weight Constraints

Determine the available space and weight limitations for the engine.

- Compact Designs: Inline CISON engines are ideal for applications with tight space constraints.

- Lightweight Configurations: V-Twin engines offer a balance of power and reduced weight, suitable for motorcycles or small machinery.

Fuel Compatibility

- Low-Cetane Fuels: Choose a CISON engine with a high compression ratio to optimize combustion.

- Hybrid Applications: For hybrid vehicles, prioritize engines compatible with range-extending technology.

Maintenance and Reliability

Assess the maintenance requirements and reliability of the engine.

- Ease of Maintenance: Simplified architectures, like inline designs, offer easier access for repairs and servicing.

- Durability: Look for engines with advanced components designed for long operational lifespans.

Budget and Cost Efficiency

Factor in the total cost of ownership, including purchase price, fuel efficiency, and maintenance expenses.

- Initial Cost: Higher-performance models may cost more upfront but offer better long-term efficiency.

- Operational Costs: Opt for engines with reduced fuel consumption and lower emissions to save over time.

To get detailed scientific explanations of CISON Engines, try Patsnap Eureka.