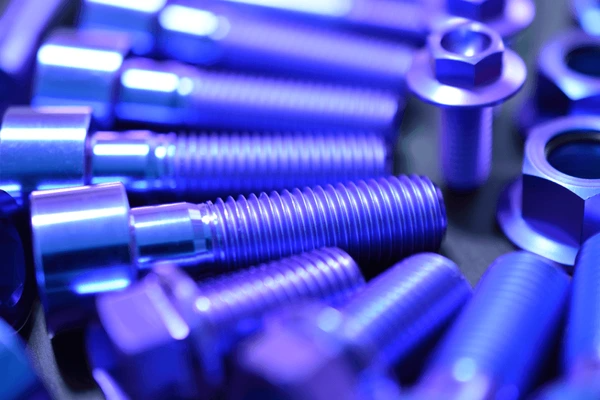

What is Anodized Titanium?

Anodized titanium refers to a process where titanium or titanium alloys are treated through anodization, a method of electrolytic passivation that increases the thickness of the natural oxidation layer on the titanium’s surface. This process involves immersing the titanium material in an electrolyte solution and applying an electric current, which leads to the growth of a thin, porous oxide layer primarily composed of titanium dioxide (TiO2).

How is Titanium Anodized?

- Preparation of the Titanium Surface: The titanium surface is cleaned and smoothed to ensure a uniform anodization process.

- Electrolytic Solution: An appropriate electrolyte solution is chosen, which can vary depending on the desired properties of the anodized layer. Common electrolytes include sulfuric acid, phosphoric acid, and solutions containing sodium hydroxide, titanium dioxide, and sodium silicate.

- Anodization Process: The titanium specimen is made the anode in the electrolytic solution, and a direct current is applied. The voltage and current density are controlled to achieve the desired thickness and properties of the anodized layer.

- Post-Anodization Treatment: After anodization, the specimen may undergo additional treatments such as thermal oxidation or hydrothermal treatment to enhance its properties.

Properties of Anodized Titanium

- Corrosion Resistance: Anodized titanium surfaces exhibit enhanced corrosion resistance due to the formation of a stable oxide layer.

- Photocatalytic Activity: The anodized layer, particularly TiO2, shows photocatalytic activity when exposed to near-UV light, which can inhibit microbial adhesion. This property is utilized to reduce bacterial and algal attachment on titanium surfaces.

- Nanoporous Structure: Electrochemical anodization can create self-organized nanoporous TiO2 structures, which have specific dependencies on anodizing potential for their structural parameters such as pore diameter and interpore distance.

Advantages and Disadvantages of Anodized Titanium

Advantages of Anodized Titanium:

- Corrosion Resistance: The oxide layer formed during anodization provides excellent corrosion resistance, making anodized titanium suitable for harsh environments.

- Hardness and Wear Resistance: The anodized layer can significantly harden the surface of titanium, improving its wear resistance and fatigue strength.

- Biocompatibility: Anodized titanium is highly biocompatible, making it ideal for medical implants and devices, where it can enhance osseointegration and reduce bacterial growth.

- Aesthetic and Functional Properties: Anodization can produce a range of colors on the titanium surface without altering its mechanical properties, which is useful for both functional and aesthetic purposes.

- Surface Modification: The process allows for the creation of nano-scale surface features, such as nanotubular structures, which can improve cellular responses and drug delivery capabilities.

Disadvantages of Anodized Titanium:

- Complexity and Cost: The anodization process can be complex and costly, especially when dealing with large or complex shapes.

- Potential for Surface Contamination: Improper handling of the anodization process can lead to surface contamination, which may affect the biocompatibility and performance of the treated surface.

- Layer Thickness and Uniformity: Achieving a consistent and desired thickness of the oxide layer can be challenging and may require precise control over the anodization parameters.

- Potential for Spark Formation: During the anodization process, sparks can form, which may lead to localized thermal stress and potentially degrade the physical properties of the titanium surface.

- Color Fading: The colored layer formed by anodization can wear off or fade over time, which may affect the aesthetic appearance and functional properties of the treated surface.

Applications of Anodized Titanium

- Medical Implants: Anodized titanium is widely used in medical implants such as prostheses, plates, screws, and dental implants. The anodization process enhances the biocompatibility and osseointegration of titanium, allowing for better integration with bone tissue. The nanostructured oxide layers formed by anodization can improve cellular adhesion, proliferation, and differentiation, which is crucial for the success of implants.

- Biosensing: The nanostructured surface of anodized titanium makes it suitable for use in biosensors. For example, anodized titanium nanotubes can be used as platforms for glucose biosensing due to their high surface area and bioactivity.

- Orthopedic Applications: In orthopedic applications, anodized titanium alloys are used to create surfaces that promote bone growth and reduce bacterial functions, thus enhancing the overall success rate of orthopedic implants.

- Dental Applications: Anodized titanium is used in dental implants to improve osseointegration and reduce the risk of implant failure. The surface modifications achieved through anodization can enhance the bioactivity of titanium, promoting better integration with bone.

- Photocatalytic Applications: Anodized titanium oxide nanotubes have shown promise in photocatalytic applications, such as hydrogen production via photoelectrochemical water splitting. The anatase crystalline structure of TiO2 nanotubes is particularly efficient in converting light into current.

- Corrosion Resistance: While anodization can increase the corrosion resistance of titanium in certain environments, it can also lead to a decrease in corrosion resistance in physiological solutions like PBS, depending on the anodizing conditions.

- Surface Modifications for Biocompatibility: Anodization can be used to modify the surface of titanium to make it more bioactive, which is essential for applications in medicine where implant integration with living tissue is critical.

Latest Technical Innovations in Anodized Titanium

Corrosion Resistance Enhancements:

- Anodizing of titanium in a 20 M NaOH solution under potentiostatic conditions has been shown to produce amorphous layers with low porosity, increasing the thickness of the oxide layer with anodizing voltage. However, this process slightly decreases the corrosion resistance in physiological solutions like PBS, likely due to the formation of compact titanium oxide layers.

- The incorporation of fluorine into the titanium oxide layer has been explored for potential biomedical applications, aiming to improve the corrosion resistance and possibly other functional properties.

Mechanical Stability Improvements

- Recent innovations have focused on techniques to enhance the mechanical stability of anodized titanium, such as post-surface treatments and the development of biocomposite coatings. These advancements aim to improve the material’s performance as a bone implant coating, ensuring better mechanical stability and integration with bone tissue5.

- The application of polymer layers on anodized titanium surfaces has been investigated, where the anodizing process is followed by the deposition of polymer films. This method aims to improve the mechanical properties and potentially other functional characteristics of the material6.

Bioactivity Enhancements

- Anodized titanium has been widely used in biomedical applications due to its bioactive and osteoconductive properties, which promote rapid bone integration. Recent research has focused on refining the anodizing processes to engineer specific surface structures that enhance bioactivity and osseointegration.

- The development of nanostructured oxide layers on titanium through anodic oxidation has been explored for various applications, including biomedical implants, where the nanostructuring is tailored to improve surface energy interactions and promote better integration with biological tissues.

Surface Modifications and Characterizations

- Innovations in the synthesis of anodized titanium oxide nanotube arrays have been directed towards creating highly ordered structures with specific crystalline phases, such as anatase, which exhibit improved photocatalytic properties for applications like hydrogen production.

- Techniques such as SEM, XRD, and Raman spectroscopy have been utilized to characterize the structure and properties of anodized titanium oxide layers, providing insights into their potential applications based on their morphological, structural, and compositional characteristics.

To get detailed scientific explanations of anodized titanium, try Patsnap Eureka.

Learn more

Shock Cords: Versatile Strength for Every Need

Pressure Switches: Small Devices, Big Impact

Unveiling The Lead Screw: Its Mechanism, Benefits, And Beyond