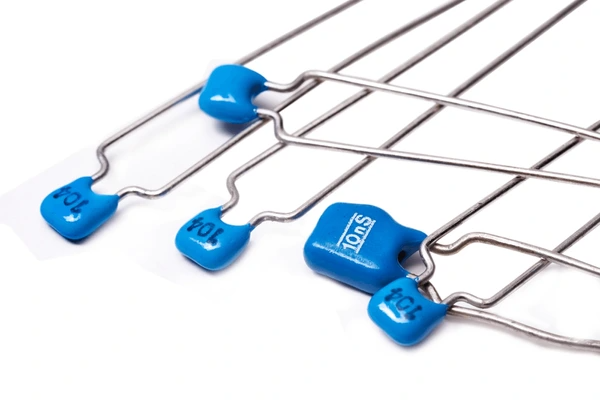

What is a Ceramic Capacitor?

Ceramic capacitors are a type of capacitor that utilizes ceramic materials as the dielectric medium. They consist of a ceramic sintered body with first and second terminal electrodes formed on the outer surfaces. The ceramic body is typically composed of a perovskite crystal structure (ABO3) containing calcium and zirconium, along with other additives like silicon, boron, and lithium.

Characteristics of Ceramic Capacitor

Dielectric Properties

Ceramic capacitors utilize ceramic materials with high dielectric constants as the dielectric layer, enabling high capacitance values in small form factors. Common dielectric materials include barium titanate (BaTiO3), calcium copper titanate (CaCu3Ti4O12), and perovskite compounds. The dielectric constant typically ranges from 3,000 to 100,000, allowing for high energy density and capacitance values.

Temperature Characteristics

The X7R classification denotes ceramic capacitors with a capacitance change within ±15% over the temperature range of -55°C to +125°C. This temperature stability is crucial for applications requiring consistent performance across varying environmental conditions. Compositional modifications, such as doping with rare earth elements and co-firing multi-phase materials, can enhance temperature characteristics.

Voltage and Energy Density

Ceramic capacitors can withstand high voltages, making them suitable for high-voltage power electronics applications. Their high dielectric constants enable high energy density, allowing for the storage of significant amounts of energy in compact sizes. This is particularly advantageous for pulsed power applications and energy storage systems.

Ferroelectric Behavior

Many ceramic capacitors exhibit ferroelectric properties due to the presence of ferroelectric materials like BaTiO3. This ferroelectric behavior results in unique discharge waveforms and high dielectric losses, which must be considered in design and cooling strategies.

Reliability and Lifetime

Ceramic capacitors are known for their excellent reliability and long lifetime, even under high electric fields and heavy current conditions. However, factors such as cracking, moisture ingress, and ionic contamination can lead to failures. Proper termination design and material selection can enhance reliability and mitigate cracking issues.

Multilayer Structure

Multilayer ceramic capacitors (MLCCs) consist of alternating layers of dielectric and internal electrode materials, enabling high capacitance values in compact sizes. The layer thickness and number of layers can be optimized to achieve desired capacitance and voltage ratings.

Types of Ceramic Capacitors

Ceramic capacitors can be broadly classified into three main categories based on their dielectric materials: Class I (Temperature Compensated), Class II (High Dielectric Constant), and Class III (Lead Lanthanum Zirconate Titanate).

- Class I (Temperature Compensated)

- Dielectric material: Titanium oxide (TiO2)

- Low dielectric constant (∈r 1

- Class II (High Dielectric Constant)

- Dielectric material: Barium titanate (BaTiO3)

- High dielectric constant (∈r > 1000)

- Compact size and high capacitance values

- Capacitance varies with voltage, temperature, and time

- Suitable for applications requiring high capacitance density, such as decoupling and filtering

- Capacitance range: up to several microfarads 13

- Class III (Lead Lanthanum Zirconate Titanate)

- Dielectric material: Lead lanthanum zirconate titanate (PLZT)

- High dielectric constant (∈r > 1000)

- Improved temperature stability compared to Class II

- Suitable for applications requiring high capacitance and temperature stability

- Capacitance range: up to several microfarads 3

Applications of Ceramic Capacitor

High-Temperature Applications

Ceramic capacitors find extensive use in high-temperature applications like downhole drilling, geothermal energy generation, power electronics, and automotive under-the-hood electronics. Conventional X7R and X8R capacitors suffer performance degradation above 150°C, necessitating the development of specialized dielectrics.

- Class I C0G Dielectrics: These nickel-based linear dielectrics exhibit highly stable capacitance up to 200°C and beyond, qualifying as X9G capacitors. They are suitable for deep well drilling and aerospace applications.

- Modified X7R Dielectrics: Recent advancements have yielded nickel-based modified X7R dielectrics with robust reliability at 175°C, expanding high-temperature capabilities.

High Voltage Applications

Ceramic capacitors with specialized dielectric compositions find applications in high-voltage power electronics and energy storage systems.

- Glass-Ceramic Dielectrics: Glass-ceramic bodies with tailored dielectric and metallization layers enable high voltage operation, with breakdown strengths of 90-200 kV/cm.

- Barium Titanate-Based Ceramics: Compositions like BaTiO3-BaZrO3-rare earth oxides exhibit intermediate to high voltage capabilities suitable for laminated ceramic capacitors.

Emerging Single-Layer Capacitors

Novel single-layer ceramic capacitors using colossal dielectric permittivity materials offer advantages like low cost, high reliability, wide temperature range (-190°C to 180°C), and potential applications across electronics, automotive, aerospace, and instrumentation sectors.

Miniaturization and Integration

Multilayer ceramic capacitors (MLCCs) with alternating dielectric and electrode layers enable high volumetric efficiency, meeting the miniaturization and integration demands of modern electronics. Ongoing R&D focuses on enhancing breakdown strength, dielectric stability, and innovative packaging.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Glass-ceramic capacitor SCHOTT AG | Utilizes glass-ceramic body as dielectric and metallization layers as electrodes, designed for high voltage applications. | High voltage power electronics and energy storage systems. |

| Dielectric ceramic and laminated ceramic capacitor Murata Manufacturing Co. Ltd. | Achieves excellent reliability and favorable high-accelerated life characteristics. | Fixed capacitors, basic electric elements, and electrical appliances. |

| Ceramic capacitor Amotech Co., Ltd. | Includes a ceramic body with multiple dielectric layers and internal electrodes, designed to prevent cracks and increase connection strength. | High reliability applications requiring robust performance under mechanical stress. |

| Single-layered ceramic capacitors | Uses novel colossal dielectric permittivity materials, offering low manufacturing cost, better reliability, and broad temperature-stable range. | Microelectronic technology, automotive, transportation, and space instrumentation. |

| Ceramic capacitor structure Holy Stone Enterprise Co., Ltd. | Features low resistance and high thermal conductivity, significantly reducing equivalent series-connection resistance. | Applications requiring high thermal conductivity and low resistance, such as advanced electronic circuits. |

Latest Innovations in Ceramic Capacitors

Materials Advancements

Ceramic capacitors have seen improvements in dielectric materials to enhance performance. New ceramic compositions like barium titanate (BaTiO3) and lead lanthanum zirconate titanate (PLZT) offer higher dielectric constants and voltage ratings. Doping and compositional modifications further optimize properties like temperature stability and energy density.

Electrode and Termination Innovations

Nickel and copper inner electrodes have replaced traditional precious metal electrodes, reducing costs. Novel termination materials like zinc-based frits enable co-firing at lower temperatures, improving reliability. Conductive polymer outer electrodes provide flexibility for wearable electronics.

Manufacturing Breakthroughs

Advanced techniques like aerosol deposition enable thinner dielectric layers (below 1 μm) for higher capacitance. 3D printing allows customized designs and embedded capacitors within components. Automated optical inspection enhances quality control.

FAQs

- What is a ceramic capacitor used for?

Ceramic capacitors are used for filtering, decoupling, energy storage, and in oscillator circuits for frequency tuning. - How does a ceramic capacitor differ from an electrolytic capacitor?

Ceramic capacitors are non-polarized, compact, and ideal for low-capacitance applications, while electrolytic capacitors are polarized and used for high-capacitance needs. - Can ceramic capacitors handle high voltage?

Yes, but their voltage rating depends on the type and size. Always choose a capacitor with a voltage rating higher than the circuit’s operating voltage. - Are ceramic capacitors polarized?

No, ceramic capacitors are non-polarized, meaning they can be connected in any direction. - What affects the performance of a ceramic capacitor?

Factors like temperature, voltage, and frequency can impact the capacitance and overall performance, especially for Class 2 capacitors.

To get detailed scientific explanations of ceramic capacitors, try Patsnap Eureka.

Learn more

Multiplexor: Efficient Data Selector for Electronics

Understanding STP Cable: Shielded Twisted Pair Explained

Understanding Twisted Pair Cable: Basics, Benefits, and Uses

JFET 101: A Beginner’s Guide to Junction Field-Effect Transistors