Graphene Battery Evolution and Objectives

Graphene batteries represent a revolutionary advancement in energy storage technology, promising to overcome the limitations of traditional lithium-ion batteries. The evolution of graphene batteries can be traced back to the discovery of graphene in 2004, which sparked intense research into its potential applications. Over the past decade, significant progress has been made in harnessing graphene’s unique properties for battery technology. The primary objective of graphene battery development is to create energy storage solutions that offer higher capacity, faster charging times, improved safety, and longer lifespan compared to conventional batteries.

Curious about graphene batteries? Eureka Technical Q&A breaks down how this cutting-edge technology boosts charging speed, capacity, and lifespan—helping you stay ahead in the future of efficient energy storage.

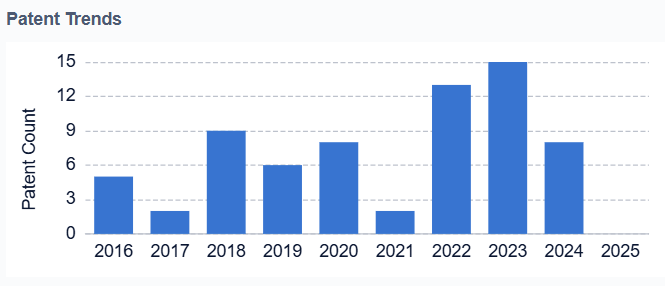

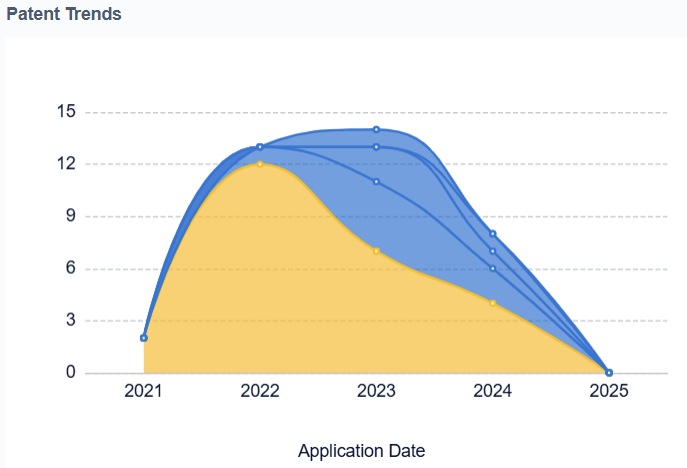

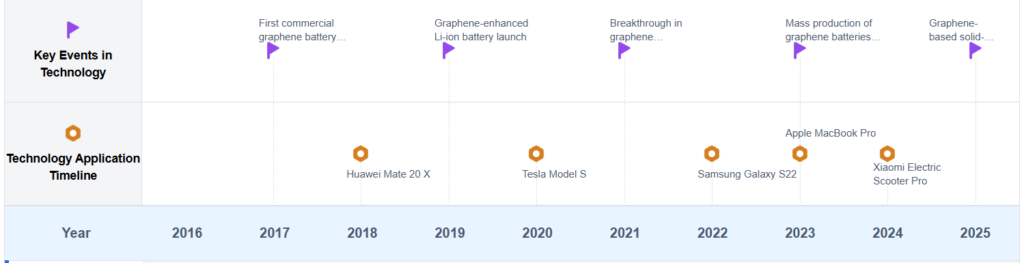

The technological trajectory of graphene batteries has been marked by several key milestones. Initially, researchers focused on incorporating graphene as an additive to enhance the performance of existing battery materials. This approach led to incremental improvements in energy density and conductivity. As the understanding of graphene’s properties deepened, efforts shifted towards developing graphene-based electrodes and electrolytes. These advancements aimed to leverage graphene’s exceptional electrical conductivity, mechanical strength, and high surface area to create more efficient battery architectures.

Recent years have seen a surge in research aimed at overcoming the challenges of mass production and scalability. The objectives now include developing cost-effective methods for large-scale graphene synthesis and integration into battery manufacturing processes. Researchers are also exploring hybrid systems that combine graphene with other advanced materials to create synergistic effects and further enhance battery performance.

Looking ahead, the goals for graphene battery technology are ambitious. Scientists and engineers are working towards achieving energy densities that surpass those of lithium-ion batteries by several orders of magnitude. There is also a strong focus on developing ultra-fast charging capabilities, with the ultimate aim of reducing charging times to mere minutes or even seconds. Additionally, researchers are targeting improvements in cycle life, aiming for batteries that can withstand thousands of charge-discharge cycles without significant degradation.

Environmental considerations are also shaping the evolution of graphene batteries. There is a growing emphasis on developing sustainable production methods and ensuring that graphene batteries are recyclable and environmentally friendly. This aligns with the broader trend towards green energy solutions and circular economy principles in the technology sector.

As the field progresses, interdisciplinary collaboration is becoming increasingly important. The objectives of graphene battery research now extend beyond pure material science, encompassing aspects of nanotechnology, electrochemistry, and manufacturing engineering. This holistic approach is essential for translating laboratory breakthroughs into commercially viable products that can revolutionize various sectors, from consumer electronics to electric vehicles and grid-scale energy storage.

Market Demand Analysis for Advanced Energy Storage

The global energy storage market is experiencing a significant shift towards advanced technologies, with graphene batteries emerging as a promising solution. Market analysis indicates a growing demand for high-performance energy storage systems across various sectors, including consumer electronics, electric vehicles, and renewable energy integration. The increasing focus on sustainability and the need for more efficient energy storage solutions are driving this demand. Graphene batteries, with their potential for higher energy density, faster charging capabilities, and longer lifespan, are positioned to address these market needs effectively.

Current market trends show a rising interest in graphene-based energy storage technologies, with several key players investing heavily in research and development. The automotive industry, in particular, is showing keen interest in graphene batteries due to their potential to overcome the limitations of traditional lithium-ion batteries in electric vehicles. Additionally, the consumer electronics sector is exploring graphene batteries to meet the demand for longer-lasting and faster-charging devices.

The market size for advanced energy storage solutions is projected to grow significantly in the coming years, with graphene batteries expected to capture a substantial share. Analysts predict that the global graphene battery market could reach several billion dollars by 2030, driven by increasing adoption in various applications and ongoing technological advancements.

However, the market demand for graphene batteries is not without challenges. The high production costs associated with graphene materials and the need for scaling up manufacturing processes are currently limiting widespread adoption. Despite these challenges, the potential benefits of graphene batteries are driving continued investment and research efforts.

Geographically, the demand for advanced energy storage solutions, including graphene batteries, is particularly strong in regions with a focus on renewable energy integration and electric vehicle adoption. Countries like China, the United States, and several European nations are at the forefront of this market trend, with significant investments in research and development of graphene-based technologies.

In conclusion, the market demand analysis for advanced energy storage, particularly graphene batteries, reveals a promising future. The technology’s potential to address key limitations of current energy storage solutions, coupled with growing environmental concerns and the push for electrification across industries, is likely to drive substantial market growth in the coming years. As research progresses and production costs decrease, graphene batteries are poised to play a crucial role in shaping the future of energy storage technologies.

Current Graphene Battery Technology Landscape

Graphene batteries represent a cutting-edge technology in the energy storage sector, offering potential advantages over traditional lithium-ion batteries. The current graphene battery technology landscape is characterized by rapid advancements and growing interest from both research institutions and industry players. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, exhibits exceptional properties such as high electrical conductivity, thermal conductivity, and mechanical strength, making it an attractive material for battery applications.

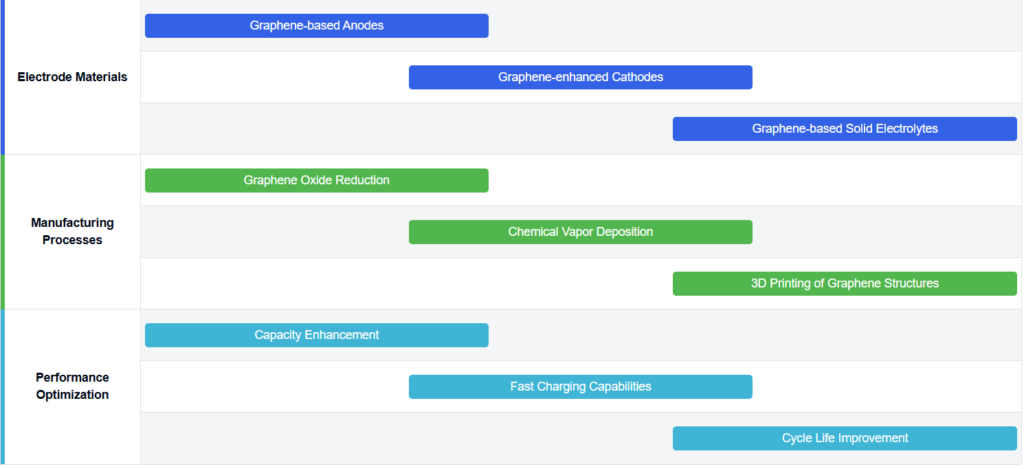

In the present landscape, graphene is primarily being explored as an enhancement to existing lithium-ion battery technology rather than as a standalone battery solution. Researchers and companies are focusing on incorporating graphene into various battery components, including electrodes, electrolytes, and current collectors. One of the most promising applications is the use of graphene as an additive in electrode materials, where it can improve the battery’s charge/discharge rates, energy density, and cycle life.

Several key innovations are driving the development of graphene batteries. Graphene-enhanced silicon anodes have shown significant improvements in energy density and cycle life compared to traditional graphite anodes. Graphene oxide-based separators are being developed to enhance battery safety and performance. Additionally, graphene-based supercapacitors are being explored as a complementary technology to batteries, offering rapid charge and discharge capabilities.

Despite these advancements, the commercialization of graphene batteries faces several challenges. The high cost of producing high-quality graphene at scale remains a significant barrier to widespread adoption. Researchers are actively working on developing more cost-effective production methods, such as chemical vapor deposition and liquid-phase exfoliation techniques.

The current graphene battery market is still in its early stages, with most products being prototypes or small-scale demonstrations. However, several companies are making significant strides in bringing graphene-enhanced batteries to market. Notable players include Samsung SDI, which has patented graphene-based battery technology, and Huawei, which has incorporated graphene-enhanced heat dissipation in its smartphone batteries.

Looking ahead, the graphene battery technology landscape is poised for further growth and innovation. Researchers are exploring novel graphene-based materials, such as graphene aerogels and graphene quantum dots, to further enhance battery performance. The integration of graphene with other advanced materials, such as metal-organic frameworks and 2D materials, is also an area of active research. As production techniques improve and costs decrease, we can expect to see more commercial applications of graphene batteries in various sectors, including consumer electronics, electric vehicles, and grid-scale energy storage.

Graphene Battery Development Timeline

Key Players in Graphene Battery Industry

The graphene battery market is in its early growth stage, characterized by rapid technological advancements and increasing commercial interest. The global market size is projected to expand significantly in the coming years, driven by the demand for high-performance energy storage solutions. While the technology is still evolving, several key players are making substantial progress in commercialization. Companies like Honeycomb Battery Co., Nanotek Instruments, and Apple are at the forefront of innovation, developing proprietary graphene-based battery technologies. Academic institutions such as Northwestern University and The University of Queensland are contributing fundamental research, while industry giants like Samsung Electronics and NEC Corp. are investing heavily in R&D. The technology’s maturity varies across applications, with some niche markets already adopting graphene batteries, while widespread commercial deployment in consumer electronics and electric vehicles is still on the horizon.

Northwestern University

Northwestern University

Technical Solution

Northwestern University has developed a graphene-based electrode material for lithium-ion batteries. Their approach involves creating a three-dimensional graphene framework with high surface area and excellent conductivity. This structure allows for faster ion transport and improved energy storage capacity. The university’s research team has also explored the use of graphene oxide as a starting material, which can be reduced to form a conductive network within the battery electrode. This method enhances the overall performance and stability of the battery.

Strengths: High surface area and conductivity, improved ion transport, enhanced energy storage capacity.

Weaknesses: Potential high production costs, scalability challenges for commercial applications.

Honeycomb Battery Co.

Technical Solution

Honeycomb Battery Co. has developed a proprietary graphene-enhanced battery technology that utilizes a honeycomb-like structure to maximize surface area and improve energy density. Their approach involves incorporating graphene into both the anode and cathode materials, creating a highly conductive and stable battery architecture. The company claims that their graphene batteries offer significantly faster charging times, increased cycle life, and higher energy density compared to traditional lithium-ion batteries. Honeycomb Battery Co. is also exploring the use of graphene in solid-state electrolytes to further enhance battery safety and performance.

Strengths: Innovative honeycomb structure, improved energy density, faster charging times. Weaknesses: Limited track record, potential high production costs.

Nanotek Instruments, Inc.

Technical Solution

Nanotek Instruments has developed a graphene-based composite material for use in high-performance battery electrodes. Their technology involves the creation of a three-dimensional graphene network that serves as a conductive scaffold for active battery materials. This structure allows for improved electron transport and ion diffusion within the electrode, resulting in enhanced battery performance. The company has also explored the use of graphene oxide as a precursor material, which can be reduced to form a highly conductive graphene network. Nanotek’s approach aims to increase energy density, power density, and cycle life of lithium-ion batteries.

Strengths: Enhanced electron transport and ion diffusion, improved battery performance.

Weaknesses: Potential scalability issues, competition from established battery manufacturers.

Apple, Inc.

Apple, Inc.

Technical Solution

Apple has been actively researching and developing graphene-based battery technologies to enhance the performance of their mobile devices. Their approach involves incorporating graphene into battery electrodes to improve conductivity and energy density. Apple’s research focuses on creating thin, flexible graphene films that can be integrated into various device form factors. The company has also explored the use of graphene in combination with other advanced materials to create hybrid battery structures. While specific details of Apple’s graphene battery technology are not publicly disclosed, patents suggest they are working on methods to enhance charging speed, increase energy storage capacity, and improve overall battery lifespan.

Strengths: Strong research and development capabilities, potential for seamless integration into existing product lines.

Weaknesses: Limited public information on specific technologies, potential high costs for initial implementation.

Samsung Electronics Co., Ltd.

Samsung Electronics Co., Ltd.

Technical Solution

Samsung has been actively developing graphene-based battery technologies to enhance the performance of their electronic devices. Their approach involves using a graphene ball material to coat the electrodes of lithium-ion batteries. This graphene coating significantly improves the battery’s charging speed and overall capacity. Samsung claims that their graphene ball technology can reduce charging times by up to five times compared to conventional lithium-ion batteries. Additionally, the company is exploring the use of graphene in flexible and wearable battery designs, leveraging the material’s excellent conductivity and mechanical properties. Samsung’s research also extends to graphene-based solid-state electrolytes for improved battery safety and performance.

Strengths: Significantly faster charging times, potential for flexible battery designs, strong research and development capabilities.

Weaknesses: Potential high production costs, competition from other major tech companies.

Existing Graphene Battery Solutions

Graphene-based electrode materials

Graphene is being utilized as an advanced electrode material in batteries due to its excellent electrical conductivity and high surface area. This innovation enhances battery performance, including faster charging times and increased energy density. Researchers are exploring various forms of graphene, such as graphene oxide and reduced graphene oxide, to optimize battery efficiency.

- Graphene-based electrode materials for batteries

Graphene-based materials are being developed and utilized as electrode materials in various types of batteries, including lithium-ion batteries. These materials offer improved electrical conductivity, higher surface area, and enhanced mechanical properties, leading to better battery performance, increased energy density, and faster charging capabilities. - Graphene composite electrodes

Researchers are developing composite electrodes that combine graphene with other materials to enhance battery performance. These composites often include metal oxides, conductive polymers, or other carbon-based materials. The synergistic effects of these combinations can lead to improved capacity, cycling stability, and rate capability in batteries. - Manufacturing processes for graphene-based battery materials

Innovations in manufacturing processes for graphene-based battery materials are emerging. These include novel synthesis methods, scalable production techniques, and advanced coating processes. These developments aim to improve the quality, consistency, and cost-effectiveness of graphene-based electrode materials for commercial battery applications. - Market trends in graphene batteries

The graphene battery market is experiencing significant growth and attracting investments. Key trends include the development of high-capacity graphene-enhanced batteries for electric vehicles, consumer electronics, and grid energy storage. There is also a focus on sustainable and eco-friendly battery technologies incorporating graphene materials.

Market trends in graphene battery adoption

The graphene battery market is experiencing rapid growth, driven by increasing demand for high-performance energy storage solutions in electric vehicles, consumer electronics, and renewable energy systems. Key market trends include collaborations between graphene producers and battery manufacturers, as well as investments in scaling up production to meet growing demand.

Integration of graphene in solid-state batteries

Researchers are exploring the integration of graphene in solid-state batteries to overcome limitations of traditional lithium-ion batteries. Graphene’s properties contribute to improved ionic conductivity and mechanical stability of solid electrolytes, potentially leading to safer and more energy-dense batteries for various applications.

Graphene-enhanced battery management systems

Innovations in battery management systems incorporating graphene-based sensors and components are emerging. These advancements enable more accurate monitoring of battery health, temperature, and charge status, leading to improved overall battery performance and longevity in various applications.

Environmental and sustainability aspects of graphene batteries

Research is focusing on the environmental impact and sustainability of graphene battery production and recycling. Efforts are being made to develop eco-friendly synthesis methods for graphene materials and to establish efficient recycling processes for graphene-based batteries, addressing concerns about resource conservation and reducing the carbon footprint of battery technologies.

Breakthrough Innovations in Graphene Electrodes

Future Research Directions for Graphene Batteries

Hybrid Graphene-Silicon Anodes

Hybrid graphene-silicon anodes are redefining the future of high-performance batteries. By combining graphene’s flexibility and conductivity with silicon’s high theoretical capacity, researchers aim to overcome the limitations of each material and build next-generation anodes with significantly higher energy density.

Silicon can store about 10 times more lithium than graphite, making it a highly attractive material for anodes. However, it expands by up to 300% during charging, which leads to cracking, capacity loss, and poor cycle life. Graphene, on the other hand, offers mechanical strength, high electrical conductivity, and flexibility. When integrated with silicon, it acts as a structural buffer, absorbing volume changes and maintaining stable electrical pathways.

How the Hybrid Structure Works

In these hybrid anodes, silicon nanoparticles or nanowires are embedded in a graphene matrix or layered between graphene sheets. This nanocomposite structure allows silicon to deliver high capacity while graphene ensures efficient electron flow and structural integrity. The design prevents pulverization and helps the electrode maintain contact with the current collector over many charge cycles.

Synthesis Techniques and Design Strategies

Researchers have explored several synthesis methods to fabricate these composites. Techniques include:

- Chemical Vapor Deposition (CVD): Growing graphene directly on silicon nanostructures

- Solution-based assembly: Mixing graphene and silicon nanoparticles in liquid media

- Graphene oxide-based synthesis: Using GO as a precursor to create reduced graphene oxide (rGO)-silicon composites

To further improve performance, engineers have experimented with 3D graphene foams and aerogels. These porous structures provide space for silicon to expand and contract without causing damage. Surface functionalization also enhances compatibility between graphene and silicon, improving the mechanical and chemical stability of the composite.

Scalability and Manufacturing Challenges

One of the major hurdles is scaling up production. While lab-scale methods yield promising results, large-scale manufacturing remains costly and complex. To address this, researchers are testing roll-to-roll methods for graphene production and refining silicon nanoparticle synthesis to reduce cost and improve uniformity.

Strengths

- Combines graphene’s conductivity with silicon’s capacity for superior energy density

- Reduces silicon’s volume expansion with flexible, robust graphene support

- Improves battery lifespan and charge stability

Weaknesses

- Manufacturing is complex and expensive

- Long-term cycle stability still requires further optimization

- Large-scale production methods are still under development

Environmental Impact of Graphene Batteries

Graphene batteries offer promising environmental advantages over traditional lithium-ion systems. Their unique properties support more sustainable energy storage solutions across industries.

Improved Efficiency and Lower Carbon Emissions

Graphene’s high conductivity and large surface area enable faster charging and discharging. This efficiency reduces the energy needed for charging cycles, which can lower overall carbon emissions over the battery’s lifetime.

Longer Lifespan Means Less Electronic Waste

Graphene batteries typically last longer than conventional lithium-ion models. Fewer replacements reduce the environmental toll from battery manufacturing and disposal. This extended life cycle contributes directly to minimizing electronic waste.

Reduced Dependence on Scarce Resources

Unlike lithium-ion batteries, graphene batteries rely on carbon—a widely available element. This shift could decrease dependency on rare earth metals and other finite materials, making battery production more sustainable long term.

Concerns Around Graphene Production

Despite the benefits, producing graphene remains energy-intensive. Many synthesis methods use harmful chemicals and generate industrial waste. To reduce environmental harm, researchers must develop cleaner, energy-efficient graphene production techniques.

Recyclability of Graphene Batteries

Early research suggests graphene batteries may be easier to recycle than lithium-ion batteries. If confirmed, this would support a more circular battery economy, with better resource recovery and reduced landfill waste.

Water Use and Pollution Risks

Manufacturers must monitor water usage and waste disposal during battery production. Optimizing processes can help prevent water pollution and reduce the environmental footprint of graphene battery manufacturing.

Support for Renewable Energy Integration

Graphene batteries could improve energy storage for solar and wind systems. Their high performance helps store intermittent energy more effectively, which supports the transition to renewable power sources and reduces fossil fuel dependence.

Scalability and Manufacturing Challenges

Scaling graphene battery production from lab to industry remains a major challenge that slows its commercial adoption. Current manufacturing methods are often complex, costly, and energy-intensive, limiting their suitability for mass production.

High-Quality Graphene at Scale Remains Elusive

Producing consistent, high-quality graphene at industrial scale is difficult. Methods like chemical vapor deposition (CVD) and liquid-phase exfoliation struggle with throughput and quality control during scale-up.

Roll-to-Roll Production Shows Promise

Researchers are exploring roll-to-roll production techniques to enable continuous, large-scale graphene synthesis. This method offers better consistency and reduced costs. However, it still needs refinement for battery-grade material.

Integrating Graphene Into Existing Battery Lines

Graphene’s unique properties demand adjustments to traditional battery fabrication processes. Ensuring even graphene dispersion and maintaining its structure during assembly remain major concerns.

To address this, researchers are testing advanced mixing, coating, and printing techniques to better integrate graphene into electrodes.

Standardization and Quality Control Are Still Lacking

Without clear industry standards, evaluating graphene quality remains inconsistent. This lack of standardization makes it hard to compare batches or ensure reliable performance.

Establishing standardized testing methods and performance metrics is crucial for scaling production and winning customer trust.

Environmental and Safety Concerns Must Be Addressed

Although graphene is relatively safe, its production may involve toxic chemicals and generate hazardous byproducts. To ensure long-term viability, manufacturers must develop greener, more sustainable production methods.

Pilot Facilities Offer a Bridge to Commercialization

Several companies and research labs are now launching pilot-scale facilities. These centers aim to test scalable production, cut costs, and improve reliability.

As these initiatives progress, they will help overcome the barriers to industrial-scale graphene battery production.

To get detailed scientific explanations of graphene batteries, try Patsnap Eureka.