What is a Wheatstone Bridge?

A Wheatstone bridge is a precise electrical circuit designed to measure unknown resistance by balancing two legs of the circuit. It consists of four resistors, including one variable resistor, and a galvanometer to detect current imbalances. By achieving balance, the circuit provides highly accurate resistance measurements, surpassing the precision of simple voltage dividers. This versatile tool is widely used in applications such as strain gauge measurements, temperature sensing, and magnetic field detection. With advancements like TMR sensors, it now offers enhanced sensitivity and accuracy. This article will explore the working principles, benefits, and real-world applications of the Wheatstone bridge.

Principle of Wheatstone Bridge: How It Works

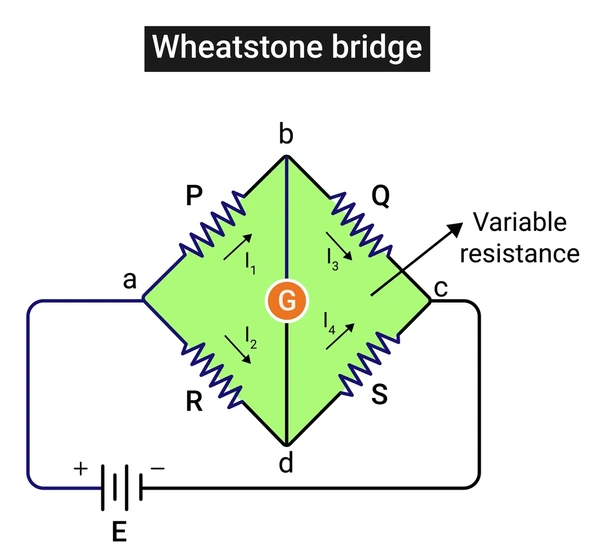

Basic Structure

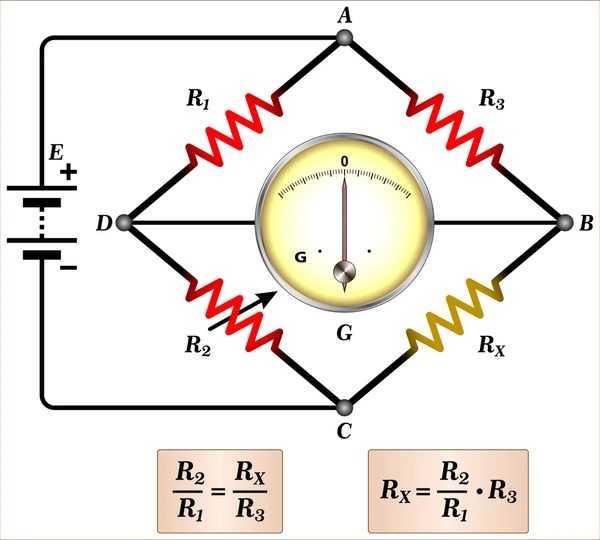

This circuit features four resistors arranged in a diamond-shaped configuration. One arm contains the unknown resistance (Rx), while the other arms house three known resistances (R1, R2, and R3). A voltage source powers the circuit, and the voltage across Rx is measured to determine its value.

Achieving Balance

The circuit achieves balance when the voltage across the unknown resistance reaches zero. This occurs when the resistance ratios in the two legs are equal, following the equation R1/Rx = R2/R3. Achieving this balance ensures accurate measurements.

How It Works

To determine the unknown resistance, one of the known resistances is adjusted until the circuit reaches balance. Once balanced, the value of Rx is calculated using the resistance ratios and the measured voltage.

Key Components of a Wheatstone Bridge Circuit

Four Resistors

The circuit features four resistors arranged in a diamond-like configuration. Three resistors have known values (R1, R2, and R3), while the fourth (Rx) represents the unknown resistance to be measured.

Variable Resistor (Rheostat)

One of the known resistors, typically R3, is adjustable to balance the circuit. This allows precise fine-tuning for accurate resistance measurement.

Voltage Source

A connected power source provides the necessary voltage to enable current flow through the circuit, ensuring proper operation.

Galvanometer or Multimeter

A galvanometer or multimeter detects voltage or current imbalances in the circuit. It helps determine when the circuit is balanced and the unknown resistance can be calculated.

Operational Amplifier (Optional)

In some setups, an operational amplifier boosts the output signal, improving sensitivity and accuracy for more precise measurements.

Integrated Sensors

The circuit can include sensors like LDRs, pressure sensors, or magnetic sensors. These additions allow measurement of light intensity, pressure, or magnetic fields in various applications.

Advantages and Limitations of Wheatstone Bridges

Advantages

- High Accuracy and Sensitivity

This circuit’s differential measurement principle ensures high accuracy and sensitivity, particularly in full-bridge equal-arm configurations. It also minimizes interference, boosting system reliability and precision. - Versatility in Applications

Initially developed for resistor characterization, the design now extends to advanced platforms like optical metatronics, microwave waveguides, and silicon photonics. Its applications range from nanoparticle analysis to bioengineering and microfluidics, operating across frequency bands from microwaves to visible light. - Dynamic Response and Stability

With thin-film strain gauges, the circuit offers enhanced stability and dynamic response. It also provides anti-vibration capabilities, ensuring better durability in demanding environments. - Simplicity and Robustness

The straightforward design allows for easy implementation and robust performance, making it a reliable choice for various sensor systems.

Limitations

- Complex Signal Conditioning

While the basic design is simple, adding signal conditioning circuits can increase complexity, particularly in current-mode applications. - Higher Power Consumption

Traditional setups may consume more power compared to alternatives like resistive voltage dividers, which mimic functionality more efficiently. - Limited High-Frequency Performance

Although adaptable to various frequency ranges, its performance diminishes at very high frequencies compared to specialized circuits. - Environmental Sensitivity

Factors like supply voltage, internal resistance, and temperature can affect sensitivity, often requiring compensation circuits for accuracy. - Overload Protection Challenges

Conventional designs may lack built-in overload protection, risking sensor failure. Specialized anti-overload features are essential for high-demand applications.

Applications of Wheatstone Bridge

Four Resistors

The circuit features four resistors arranged in a diamond-like configuration. Three resistors have known values (R1, R2, and R3), while the fourth (Rx) represents the unknown resistance to be measured.

Variable Resistor (Rheostat)

One of the known resistors, typically R3, is adjustable to balance the circuit. This allows precise fine-tuning for accurate resistance measurement.

Voltage Source

A connected power source provides the necessary voltage to enable current flow through the circuit, ensuring proper operation.

Galvanometer or Multimeter

A galvanometer or multimeter detects voltage or current imbalances in the circuit. It helps determine when the circuit is balanced and the unknown resistance can be calculated.

Operational Amplifier (Optional)

In some setups, an operational amplifier boosts the output signal, improving sensitivity and accuracy for more precise measurements.

Integrated Sensors

The circuit can include sensors like LDRs, pressure sensors, or magnetic sensors. These additions allow measurement of light intensity, pressure, or magnetic fields in various applications.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Physics Lab Equipment | Used to find unknown resistance by balancing the bridge circuit with known resistances. | Electrical engineering labs, physics experiments to study resistance. |

| Hard Disk Drives Western Digital Technologies, Inc. | Enables precise measurement of tunneling magnetoresistive (TMR) sensors by reducing surface roughness through chemical mechanical planarization. | Hard disk drive manufacturing, magnetic sensor characterization. |

| Metatronic Analogues | Extends the Wheatstone bridge concept to optical metamaterials, enabling characterization in different frequency regimes from microwaves to visible light. | Nanophotonic applications, nanoparticle characterization. |

| Wheatstone Bridge Circuits Sensata Technologies, Inc. | Eliminates the need for extra sensors, reducing cost and simplifying calibration algorithms in AC/DC measurement applications. | Electrical equipment, semiconductor devices, instrumentation. |

Latest Technical Innovations in Wheatstone Bridge

Advanced Platforms and Applications

Innovations extend precision measurement principles to optical and microwave platforms, enabling metamaterial boards, waveguides, and silicon photonic systems to operate across various frequency ranges.

Enhanced Torque Sensors

Torque sensors now use thin film technology to protect against overload, ensuring durability, high sensitivity, and improved accuracy through balanced resistance configurations.

Thermistor Resistance Studies

Precise resistance measurement techniques provide accurate thermistor readings, revealing their temperature relationships under controlled conditions with minimal deviation.

TMR Manufacturing Advancements

Precision arrays support Tunnel Magnetoresistance (TMR) in chemical mechanical planarization, ensuring accurate results in advanced electronics manufacturing.

To get detailed scientific explanations of Wheatstone Bridge, try Patsnap Eureka.