Core Synthesis Methodologies

Radical Polymerization Techniques

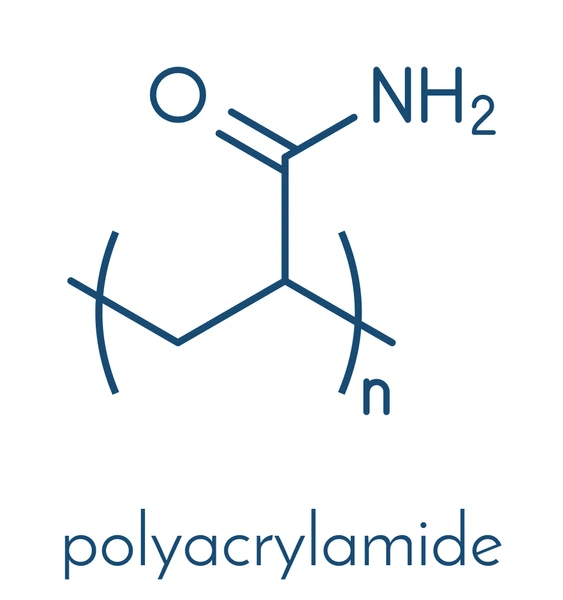

Polyacrylamide synthesis predominantly relies on free-radical polymerization, with process variations determining molecular architecture. Aqueous solution polymerization (20-30% monomer concentration) achieves linear chains with molecular weights up to 15 MDa. For specialized applications like oil recovery, inverse emulsion polymerization produces microemulsions with 2-15% solids content, enabling rapid hydration (<30 minutes) upon field dilution. Recent advances in template polymerization allow precise control over charge distribution in cationic polyacrylamide (CPAM), achieving charge densities of 3-8 meq/g through acrylamide/trimethylammonium ethyl methacrylate copolymerization.

Biocatalytic Monomer Production

BASF’s innovation revolutionized acrylamide synthesis via nitrile hydratase enzymes, eliminating copper catalysts and achieving >99% conversion at 10-15°C. This bio-based method reduces acrylic acid impurities to <0.05%, critical for high-purity applications like electrophoresis gels. The 2021 iteration introduces staggered biocatalyst dosing, controlling exothermic peaks below 30°C and enabling reactor downsizing by 40%.

Structure-Property Relationships

- Molecular Architecture Engineering

Copolymerization with acrylic acid introduces carboxyl groups (-COOH) density up to 30 mol%, enabling pH-responsive swelling with 500% volume change between pH 3-9. Sulfonate functionalization via lignosulfonate grafting enhances thermal stability, with the glass transition temperature increasing from 165°C to 195°C for paper strengthening applications. Crosslinking density optimization balances swellability (600% maximum) and compressive modulus (50-200 kPa) in biomedical hydrogels. - Degradation Mechanisms

Field applications demand controlled degradation profiles. Ultrasonic degradation rates reduce molecular weight from 12 MDa to 0.8 MDa in 60 minutes. Biodegradation studies show Pseudomonas sp. strains achieving 78% mineralization in 28 days under aerobic conditions. Thermal stability thresholds define safe processing at <80°C, with accelerated degradation occurring above 120°C.

Industrial Application Paradigms

Water Treatment Systems

CPAMs dominate flocculation processes, with 95% turbidity reduction at 2-5 ppm dosages in municipal wastewater. Charge density optimization (4-6 meq/g) enables dual charge neutralization and bridging flocculation, critical for removing colloids smaller than 2 μm. Polyacrylamide integrated with Gemini surfactants (C12-14 alkyl chains) in drilling fluids reduces shale swelling by 60% while maintaining low-shear viscosity at 30 cP.

Enhanced Oil Recovery (EOR)

High-molecular-weight variants (8-15 MDa) achieve 50% viscosity enhancement at 0.1% concentration in brine (30 g/L NaCl). The graft copolymer with dextran (25 wt%) shows 85% friction reduction at 5 bpm flow rates, critical for hydraulic fracturing. Field data confirms 15-20% incremental oil recovery in mature reservoirs through improved sweep efficiency.

Biomedical Innovations

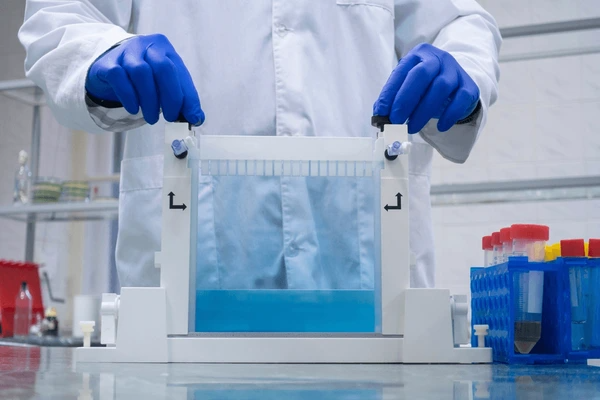

KL grade 2/3 osteoarthritis treatment using 4% crosslinked hydrogels demonstrates 26-week pain reduction and 15° flexion improvement. Electrophoresis gels with triethanolamine buffer maintain less than 5% hydrolysis after 12-month storage, enabling precise protein separation. Drug delivery matrices exhibit zero-order release kinetics over 72 hours for dexamethasone.

Emerging Technological Frontiers

Smart Responsive Hydrogels

Polyacrylamide/polyvinyl alcohol/graphite interpenetrating polymer network (IPN) composites achieve 0.8 S/cm conductivity and 500% stretchability, enabling wearable sensor integration. Temperature-responsive variants using N-isopropylacrylamide co-monomers show abrupt swelling transitions at 32°C, ideal for triggered drug release.

Advanced Manufacturing Techniques

Microplate geometry (200 μm thickness, 5 mm² plates) achieves 90% hydration in under 2 minutes, revolutionizing field deployment. Adiabatic polymerization reactors enable continuous production at 500 kg/hr with less than 1% batch variability through pressure-resistant design.

Environmental Impact Mitigation

Lifecycle analyses compare bio-based vs traditional synthesis: 62% lower energy consumption and 85% reduced copper sludge. UV/H2O2 advanced oxidation for wastewater treatment degrades 98% residual polymer within 30 minutes.

Future Research Trajectories

- AI-Driven Formulation Optimization: Machine learning models predicting copolymer sequence-property relationships

- Enzyme-Embedded Systems: Nitrile hydratase-functionalized membranes for in situ monomer purification

- 4D Printing Applications: Spatiotemporally controlled hydrogel actuators with <50 μm resolution

Conclusion

Polyacrylamide’s versatility stems from tunable synthesis-structure-property relationships, enabling solutions from megaton-scale water treatment to precision biomedicine. The field is transitioning from empirical formulation to predictive design, driven by bio-catalysis advances and smart material paradigms. Future breakthroughs will likely emerge at the polymer-inorganic interface and through closed-loop lifecycle management systems. Sustained R&D investment in degradation technologies and renewable feedstocks remains critical for maintaining the polymer’s license to operate in increasingly regulated markets.

To get detailed scientific explanations of polyacrylamide, try Patsnap Eureka.