What Is a Straight Engine?

A straight engine, also called an inline engine, is a widely used type of internal combustion engine. In this design, the cylinders are aligned in a single row, parallel to the crankshaft. Known for its simplicity and efficiency, the straight engine is one of the most traditional and reliable engine configurations, commonly found in cars, motorcycles, and other vehicles. This article explores how straight engines work, their advantages, and why they remain popular in modern vehicles.

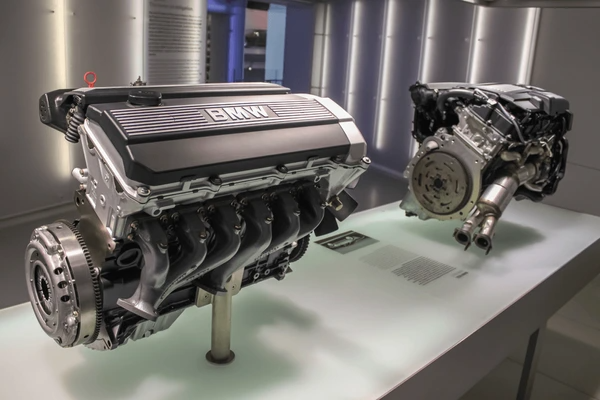

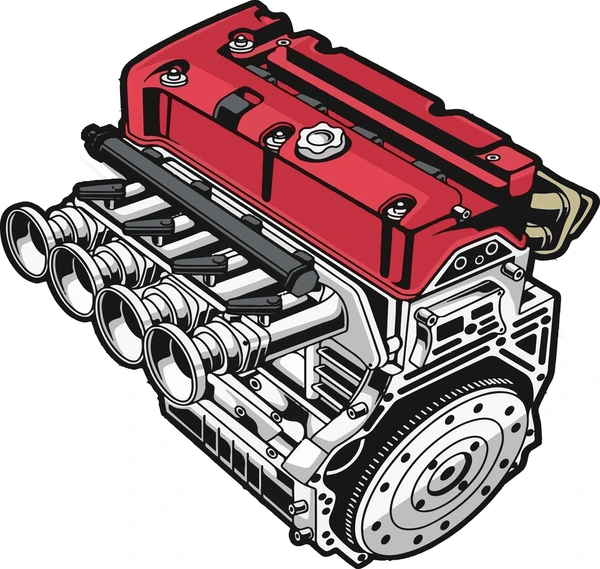

Straight Engines: Working Principles and Key Components

Straight engines, also known as inline engines, are a type of internal combustion engine where the cylinders align in a single row along the crankshaft. This design is popular for its compact construction, efficient power transfer, and reduced vibration levels. Here’s a closer look at the key components and how they work together in a straight engine.

Cylinder Block and Cylinders

The cylinder block forms the core of a straight engine. It houses the cylinders, where the combustion process takes place. In most designs, the cylinders are arranged in a straight line with an even number, such as 4, 6, or 8. This arrangement ensures better balance and smoother engine operation, reducing vibrations and enhancing efficiency.

Crankshaft and Connecting Rods

The crankshaft converts the up-and-down motion of the pistons into rotational motion. Connecting rods link the pistons to the crankshaft, transferring the force generated during combustion. Many straight engines include counterweights on the crankshaft to balance the reciprocating forces and minimize vibrations, ensuring a smoother driving experience.

The Combustion Process

Straight engines operate using the four-stroke cycle, which includes intake, compression, power, and exhaust strokes:

- Intake Stroke: The piston moves down, drawing the air-fuel mixture into the cylinder.

- Compression Stroke: The piston moves up, compressing the mixture to prepare for ignition.

- Power Stroke: The spark plug ignites the compressed mixture, creating high-pressure gases that push the piston downward, generating power.

- Exhaust Stroke: The piston moves up again, expelling the burnt gases through the exhaust valve.

This cycle repeats in each cylinder, providing the power needed to rotate the crankshaft and propel the vehicle.

Valve Train and Timing

The valve train includes the valves, camshafts, and other components that control gas intake and exhaust. Proper timing of valve operation is essential for optimal engine performance. A timing chain or belt connected to the crankshaft ensures precise synchronization of the valve train with the combustion process.

Lubrication and Cooling Systems

Straight engines rely on efficient lubrication and cooling systems to maintain performance and durability:

- Lubrication System: This system delivers oil to moving parts, reducing friction and preventing wear.

- Cooling System: A liquid coolant circulates through the engine block and radiator to dissipate heat generated during combustion.

These systems work together to keep the engine running smoothly and prevent overheating.

Key Features of Straight Engines

Advanced Features of Straight Engines: Precision, Monitoring, and Optimization

Straight engines offer advanced features that enhance efficiency, reliability, and adaptability. These capabilities make them a powerful choice for modern vehicles. Let’s explore how straight engines achieve precise control, advanced diagnostics, and data-driven optimization.

Precise Fuel and Ignition Control

Straight engines enable precise adjustments to fuel delivery, timing, and the air-fuel ratio for each cylinder. These fine-tuned controls ensure optimized combustion and maximize power output. By tailoring these parameters for every revolution, straight engines achieve better fuel efficiency and smoother performance.

Advanced Cylinder Monitoring and Diagnostics

Straight engines can monitor key parameters such as the top dead center position, fuel quality, and power stroke for each cylinder. This real-time monitoring helps identify potential issues, including cylinder wear, leaks, misalignment, or imbalances. By detecting these problems early, the engine can predict component failures and recommend timely maintenance.

Flexible Operation for Efficiency

Straight engines excel in adapting to changing operating conditions. They can adjust spark ignition timing, duration, and the fuel-air mixture on a cylinder-by-cylinder and revolution-by-revolution basis. This flexibility allows the engine to perform efficiently under varying loads and with different fuel qualities, making it highly versatile.

Comprehensive Vehicle Diagnostics

In addition to engine-specific diagnostics, straight engines can identify issues in other vehicle systems. For example, they can analyze how the engine reacts to problems in the brakes or drivetrain. This integrated approach provides a more complete picture of the vehicle’s overall health, enabling comprehensive diagnostics.

Data-Driven Optimization and Maintenance

Straight engines store historical data on engine and cylinder performance. They use this information to optimize efficiency, power, and longevity over time. Adaptive learning and predictive maintenance strategies allow the engine to make data-driven adjustments, ensuring peak performance while reducing wear and tear.

Advantages of Straight Engines Over Other Configurations

Compact Design and Key Advantages of Straight Engines

Straight engines are known for their simplicity, efficiency, and compact design. These features make them a popular choice for many vehicle applications. Let’s explore how their design and architecture offer distinct benefits.

Compact and Space-Saving Design

Straight engines feature a narrow and compact design, making them easier to fit into vehicles. Their streamlined layout creates more space for other components, such as the operator’s cabin, suspension systems, or cargo storage. Engineers often offset the cylinders inward to reduce the gap between them, further enhancing the engine’s compactness.

Simplified Architecture for Easy Maintenance

With all cylinders arranged in a single line, straight engines have a simplified architecture. This setup allows for straightforward placement of components like fuel injectors, intake manifolds, and exhaust manifolds. The open design eliminates the need for complex routing, making the engine easier to assemble, maintain, and repair.

Reduced Reciprocating Mass

Straight engines use fewer connecting rods and a simpler crankshaft design compared to other configurations, such as V or opposed-piston engines. This reduction in reciprocating mass decreases the engine’s weight and improves overall efficiency. Additionally, the simpler crankshaft design requires fewer throws, contributing to a lighter and more compact engine.

Improved Balance and Smoother Operation

The inline arrangement of cylinders ensures better primary and secondary balance. This design minimizes vibrations and provides smoother operation, even at higher engine speeds. As a result, straight engines deliver a more comfortable driving experience with less noise and wear on components.

Efficient Packaging of Ancillary Components

The compact and open layout of straight engines makes it easier to package ancillary components like generators, electric motors, and transmission systems. This efficient design results in a more space-saving powertrain layout, allowing manufacturers to optimize vehicle design for performance, comfort, or additional storage.

Common Applications of Straight Engines

1. Construction and Mining Equipment

Straight engines power heavy machinery like crawler hydraulic shovels and excavators, commonly used in construction and mining. These machines feature separate drive sections on the right and left sides, each controlled by dedicated motors.

Operating them for long hours requires precise coordination of both sides, which can be tiring for operators. To solve this, many systems now include a constant-speed straight-driving mode. This feature maintains a straight path automatically, reducing operator fatigue and increasing productivity in demanding environments.

2. Material Handling and Logistics

Linear motors are widely used in automated storage and retrieval systems, especially in automated parking garages. In these systems, a series of linear motors, installed on the floor, act as primaries, while the vehicle platforms serve as secondaries.

Computerized control enables efficient movement of vehicles, optimizing space utilization and operational efficiency. This innovative approach is transforming how parking garages and storage facilities operate, making them faster and more space-efficient.

3. Industrial Machinery and Robotics

Linear motors are rapidly replacing traditional lead screw drives in CNC machine tools and industrial robots. Their ability to provide direct linear motion eliminates the need for rotary-to-linear conversion mechanisms.

This results in several advantages, including:

- Higher acceleration: Improved speeds for manufacturing processes.

- Greater positioning accuracy: Precision for delicate operations.

- Reduced maintenance: Fewer moving parts mean lower wear and tear.

These benefits make linear motors a preferred choice for industrial machinery and robotics, enhancing performance and reducing downtime.

4. Transportation and Consumer Applications

Linear induction motors play a vital role in enabling high-speed maglev trains by providing both levitation and propulsion forces. These motors allow for smooth, high-speed travel with minimal friction, revolutionizing transportation.

In the consumer sector, linear motors enhance various household appliances, including washing machines, refrigerators, and sewing machines. They provide precise motion control, energy efficiency, and quieter operation, improving the user experience and reducing energy consumption.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Circuit Board Assembly Honor Device Co., Ltd. | Ensures larger solder joints between pads, improving connection strength. | Electronic devices requiring robust interconnections between components. |

| Inductor Positioning Technology ASTEC INTERNATIONAL LIMITED | Positions inductor coils above circuit components, enhancing inductor size and efficiency while providing thermal and mechanical support. | Electronic circuits with space and design constraints for large inductors. |

| Electric Connector Assembly Foxconn (Kunshan) Computer Connector Co., Ltd. | Designs connectors and uses conductive gaskets and tapered alignment to prevent thermal damage and enable easy assembly/maintenance. | Circuit boards requiring convenient component connections and maintenance. |

| Wiring Circuit Board Nitto Denko Corp. | Controls posture of electronic elements with certainty using pedestal parts and ground terminal arrangement. | Circuit boards with electronic components requiring precise positioning. |

| Printed Circuit Board Samsung Electro-Mechanics Co., Ltd. | Bonds core portions with embedded passive components using conductive particles, improving power integrity and design flexibility. | Printed circuit boards requiring integrated passive components. |

To get detailed scientific explanations of Straight Engine, try Patsnap Eureka.