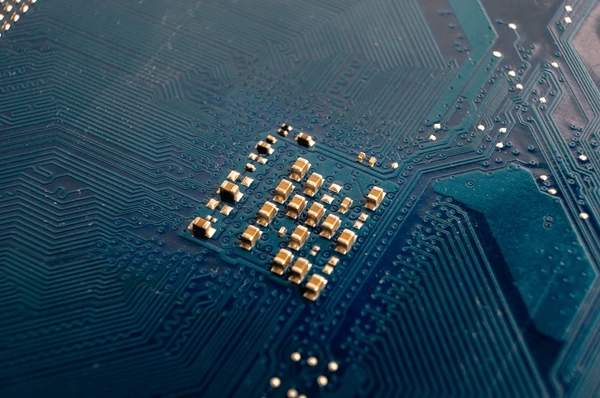

What Are SMD Components?

SMD (Surface Mount Device) components are compact electronic components specifically designed for surface mounting on printed circuit boards (PCBs). Unlike traditional through-hole components, which have leads that pass through holes in the PCB, SMD components feature flat terminals or leads that are soldered directly onto the PCB’s surface. This design allows for smaller, lighter, and more efficient circuit layouts, making SMD components a popular choice in modern electronics. In this article, we’ll explore the advantages of SMD components, their applications, and why they are integral to today’s technology.

Types of SMD Components

1. Passive Components

These components do not require an external power source to operate and are essential for regulating signals and energy in circuits.

- Resistors: Control current flow and adjust signal levels.

- Capacitors: Store and release electrical energy, filter signals, and stabilize voltage.

- Inductors: Manage energy in the form of a magnetic field, used in filtering and signal processing.

- Filters: Remove unwanted frequencies or noise from a circuit.

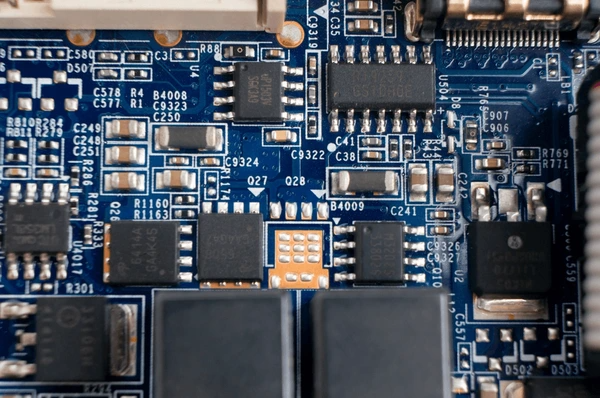

2. Active Components

Active components rely on external power to function and can amplify signals or control current flow.

- Integrated Circuits (ICs): Miniaturized circuits with multiple functions, used in processors, memory, and more.

- Transistors: Act as switches or amplifiers in electronic circuits.

- Diodes: Allow current to flow in one direction, often used for rectification.

- LEDs (Light-Emitting Diodes): Emit light when an electric current passes through, commonly used for displays and indicators.

3. Electromechanical Components

These components combine electrical and mechanical properties to perform switching or connection tasks.

- Switches: Control the flow of current by opening or closing a circuit.

- Connectors: Provide a secure interface between different circuit elements or external devices.

- Relays: Electrically operated switches used to control circuits.

Manufacturing Process of SMD Components

1. Component Fabrication

First, the fabrication process begins with crafting the body and terminals of the components. Manufacturers use materials such as ceramics, metals, or plastics, depending on the type of component. Moreover, advanced manufacturing techniques ensure consistent quality and enable the miniaturization required for modern electronic devices.

2. Application of Solder Paste or Adhesive

Next, solder paste or conductive adhesive is applied to the designated pads on the PCB. This step is critical as it prepares the board for mounting components. Additionally, the paste ensures secure electrical and mechanical connections once the assembly process is complete.

3. Accurate Component Placement

After applying the solder paste, pick-and-place machines position the SMD components onto the PCB with high precision. These automated systems are programmed to handle a wide variety of component shapes and sizes. Furthermore, they ensure accurate alignment, which is vital for optimal functionality.

4. Reflow Soldering or Curing

Finally, the assembled PCB undergoes reflow soldering or curing. During reflow soldering, the board passes through a specialized oven where controlled heat melts the solder paste, forming permanent connections. On the other hand, adhesive-based processes involve curing, which hardens the adhesive and secures the components in place. This final step ensures the components remain firmly attached during operation.

Advantages of SMD Components Over Through-Hole Components

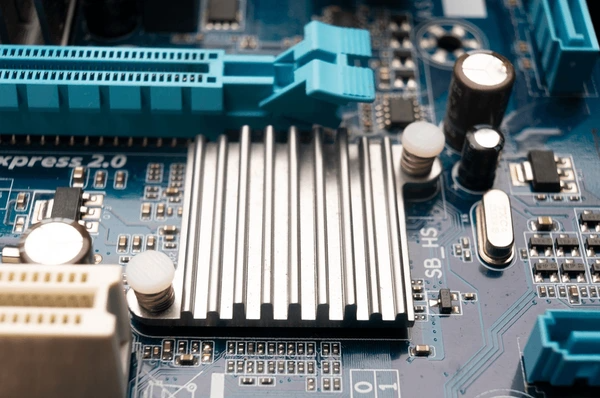

Compact Size and Lightweight Design

SMD components are smaller and lighter than their through-hole counterparts because they have either smaller leads or no leads at all. This compact design allows for higher component density on PCBs, enabling the miniaturization of electronic devices. Furthermore, the reduced weight contributes to lighter and more portable products, a crucial factor in modern consumer electronics.

Improved Electrical Performance

With shorter interconnection lengths, SMD components provide lower inductance and resistance, enhancing their high-frequency performance. This reduced signal interference makes them ideal for high-speed and radio-frequency applications, where precision and stability are critical.

Automated Assembly and Cost Efficiency

SMD components are designed for surface mounting, which simplifies automated assembly processes. Automated production improves efficiency, reduces manual labor, and lowers manufacturing costs. As a result, SMD technology supports mass production without compromising quality.

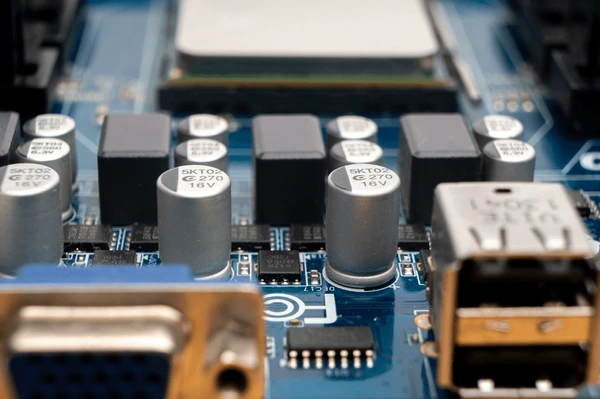

Enhanced Reliability

By eliminating the leads that pass through PCBs, SMD components reduce mechanical stress points. This design improves durability, especially in applications exposed to vibration or shock. Their compact and robust construction ensures long-term reliability, even in harsh environments.

Better Thermal Management

The surface-mount design allows heat to dissipate more effectively from the component to the PCB. This improved thermal performance enhances power handling capabilities, making SMD components suitable for high-power applications.

Greater Design Flexibility

SMD components can be mounted on both sides of a PCB, maximizing the use of available space. Their flat contacts and ball grid arrays also offer flexible PCB routing and layout options. This design flexibility enables more compact and intricate circuit designs, meeting the demands of modern electronic innovations.

Applications of SMD Components in Electronics

Consumer Electronics

SMD components are essential in devices like smartphones, tablets, laptops, and wearables. Their small size and lightweight design enable the production of sleek, portable gadgets. Additionally, their reliability ensures consistent performance in devices used daily.

Automotive Electronics

In the automotive sector, SMD components are used in sensors, advanced lighting systems, and infotainment units. These components withstand harsh conditions, including temperature variations and vibrations, ensuring durability and safety in vehicles.

Industrial and Medical Equipment

Industrial control systems and medical instrumentation rely on SMD technology for precision and reliability. From monitoring devices to advanced automation systems, these components support efficient operation and accurate results in critical applications.

Aerospace and Defense

SMD components play a vital role in avionics, radar systems, and communication devices for aerospace and defense. Their ability to perform under extreme conditions and their compact size make them suitable for space-constrained and high-performance environments.

To get detailed scientific explanations of SMD components, try Patsnap Eureka.