Introduction

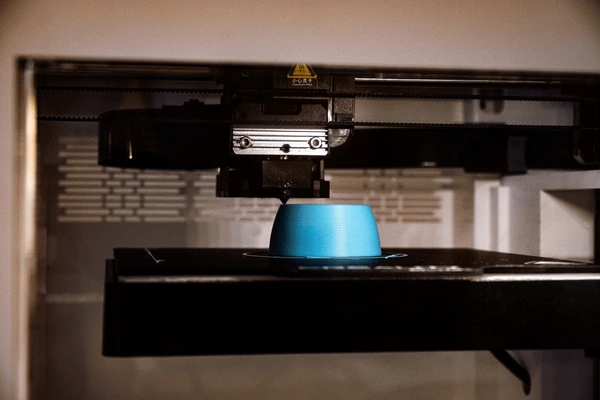

When it comes to 3D printing, selecting the right filament can make all the difference in achieving the best results. PLA vs. PLA+ are two popular options, each offering unique features and benefits. While PLA is known for its ease of use and environmental friendliness, PLA+ takes it a step further with enhanced strength and durability. Deciding between these materials depends on factors like your project’s requirements, desired finish, and budget. This article provides a complete guide to PLA and PLA+, comparing their properties, advantages, and best use cases to help you make an informed choice for your next 3D printing project.

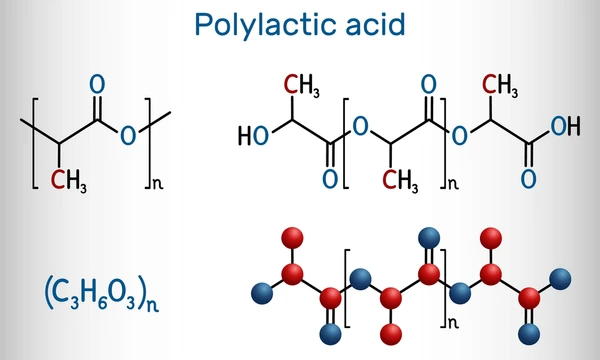

Key Properties of PLA

- Biodegradability: PLA stands out for its ability to decompose naturally in the environment, making it a sustainable alternative to traditional plastics. This property helps reduce plastic waste and supports eco-friendly practices.

- Strong Mechanical Properties: PLA offers impressive mechanical properties, including tensile strength and elasticity, comparable to petroleum-based plastics like PET. These qualities make it a reliable choice for a wide range of applications.

- Excellent Optical Properties: With high optical purity, PLA is ideal for medical and packaging uses where transparency and clarity are essential. Its ability to meet aesthetic and functional needs adds to its versatility.

- Controlled Crystallization: The crystallization rate of PLA can be adjusted through structural modifications and nucleating agents. These adjustments enhance its performance, making it suitable for more demanding applications.

Enhanced Features of PLA+

Improved Mechanical Properties

- Nanostructures in PLA: Adding well-dispersed nanostructures significantly boosts PLA’s strength, rigidity, and impact resistance. For example, incorporating silane-modified glass fibers (m-GF) increases mechanical performance substantially. A composite with 20 wt% glass fibers achieves nearly double the strength and rigidity and more than triple the impact toughness compared to pure PLA.

- Carbon Fiber and Graphene Reinforcement: Multi-scale reinforcement with carbon fiber (CF) and graphene oxide (GO) offers even greater benefits. A blend of 0.5 wt% GO and 9 wt% CF enhances tensile strength by 73.33%, tensile modulus by 231.71%, and bending strength by 89.83%, delivering remarkable improvements over pure PLA.

Enhanced Thermal Properties

- Glass Fiber Integration: Adding silane-modified glass fibers increases PLA’s thermal stability, evidenced by a higher heat deflection temperature. This improvement makes PLA more suitable for applications involving elevated temperatures.

- Humic Acid Effects: Incorporating humic acid (HA) slightly enhances thermal stability but reduces glass transition (Tg) and melting temperatures (Tm). While this limits some high-temperature applications, it provides opportunities for specific niche uses.

PLA vs PLA+: Strength and Durability Comparison

Toughness and Impact Resistance

- PLA: While PLA is easy to work with, it tends to be brittle and lacks toughness. This brittleness limits its use in applications where durability is crucial.

- PLA+: PLA+ offers significantly better impact resistance and toughness. It is more robust, less prone to cracking, and suitable for functional parts and mechanical applications.

Layer Adhesion and Flexibility

- PLA: PLA provides decent layer adhesion but may face issues with layer integrity due to its brittle nature, especially in larger prints.

- PLA+: With improved layer adhesion and added flexibility, PLA+ reduces the likelihood of delamination. These features enhance its durability and make it better suited for demanding applications.

Print Performance

- PLA: Known for its ease of use, PLA delivers smooth surface finishes and minimal warping. It prints well without requiring an enclosed chamber.

- PLA+: PLA+ retains the simplicity of PLA printing while offering enhanced strength and dimensional stability. These improvements make it a great option for more durable and reliable prints.

Applications

- PLA: Ideal for conceptual models, rapid prototyping, and metal casting patterns, PLA is perfect for low-stress applications. Its minimal shrinkage and safety profile add to its appeal for general-purpose printing.

- PLA+: With higher strength and durability, PLA+ is suitable for functional parts and mechanical components. It excels in industries like automotive, electronics, and manufacturing, where robust and reliable materials are essential.

Choosing the Best Filament for Your 3D Printing Projects

Understand Your Project Requirements

- Purpose of the Print: Determine whether you are creating aesthetic models, prototypes, or functional parts.

- Mechanical Needs: Consider factors like strength, durability, flexibility, and impact resistance based on your project’s purpose.

- Printing Environment: Account for conditions like temperature, exposure to stress, and operational demands.

PLA: Best for Simplicity and Prototypes

- Key Advantages: PLA is affordable, easy to print, and works well for beginners.

- Ideal Uses: It is perfect for aesthetic models, rapid prototyping, and projects with minimal mechanical demands.

- Limitations: PLA is brittle and less suitable for applications requiring toughness or high durability.

PLA+: Designed for Durability and Strength

- Key Advantages: PLA+ offers enhanced strength, durability, and flexibility, making it suitable for demanding projects.

- Ideal Uses: It excels in functional parts, mechanical components, and applications in automotive, electronics, and manufacturing industries.

- Additional Benefits: It provides better layer adhesion, impact resistance, and dimensional stability compared to standard PLA.

Factors to Consider When Choosing

- Ease of Printing: Both PLA and PLA+ are easy to print, but PLA is more forgiving for beginners.

- Budget: PLA is more cost-effective, while PLA+ delivers better value for long-term and durable projects.

- Application Scope: Use PLA for non-functional prints and PLA+ for parts exposed to stress or requiring high performance.

To get detailed scientific explanations of PLA vs. PLA+, try Patsnap Eureka.