Introduction

Nitrous oxide (NOS) is a popular performance-enhancing system that provides a significant power boost for car engines. By injecting nitrous into the combustion process, it delivers more oxygen, allowing the engine to burn additional fuel and generate increased horsepower. Commonly used in racing and high-performance vehicles, NOS offers a cost-effective and efficient way to achieve greater speed and acceleration. Let’s dive into how it works, its benefits, and the precautions necessary for safe use.

What is Nitrous Oxide?

Nitrous oxide (N2O), commonly known as “laughing gas,” is a colorless, non-flammable gas with a slightly sweet odor. It is a minor component of the Earth’s atmosphere and plays an active role in the planetary nitrogen cycle. Over the past few decades, its concentration has increased significantly, with an annual growth rate of 0.2–0.3%. N2O is a potent greenhouse gas with a global warming potential approximately 300 times that of CO2 over a 100-year time scale. It also contributes to ozone layer depletion in the stratosphere.

How Nitrous Oxide Works in Cars

Chemical Composition and Oxygen Content

Nitrous oxide (N2O) contains approximately 36% oxygen by weight, compared to the 21% oxygen content in atmospheric air. When introduced into the engine’s air intake, the higher oxygen content of N2O allows for a greater amount of fuel to be combusted per unit volume of the engine, thereby increasing the power output.

Combustion Process Enhancement

The introduction of N2O into the combustion chamber enhances the combustion process by providing additional oxygen. This leads to a more complete and efficient combustion of the fuel, resulting in increased pressure within the cylinder and consequently more power generated during the power stroke of the engine cycle. The increased combustion efficiency translates to higher engine performance and acceleration capabilities.

Types of Nitrous Oxide Systems

- Dry Systems: In a dry system, nitrous oxide is injected into the air intake, and the engine’s original fuel delivery system is adjusted to provide the additional fuel required. This can involve replacing stock fuel injectors with high-flow injectors. However, dry systems have limitations as they may not be able to introduce enough fuel to react with the high volumes of oxygen provided by the nitrous oxide.

- Wet Systems: Wet systems include a separate supplemental fuel delivery system that works alongside the nitrous oxide delivery system. This allows for precise metering of additional fuel directly into the engine intake path, ensuring that the engine can fully utilize the increased oxygen content. Wet systems are generally more effective and can handle higher volumes of nitrous oxide.

Benefits of Nitrous Oxide in Cars

- Increased Horsepower: By providing more oxygen for combustion, N2O allows the engine to burn more fuel, resulting in a significant increase in horsepower. Depending on the system and engine setup, horsepower gains can range from 50 to over 200 HP.

- Improved Acceleration: The additional power from N2O can lead to faster acceleration times, making it particularly beneficial for drag racing and other high-performance applications.

- Cost-Effective Power Boost: Compared to other performance enhancements like turbocharging or supercharging, nitrous oxide systems are relatively inexpensive and easier to install.

Risks and Challenges of Using Nitrous Oxide

- Engine Stress and Damage: Nitrous oxide increases power output but adds stress to engine components. Pistons, rods, and crankshafts must handle the extra forces to prevent wear or failure.

- Risk of Detonation: Overusing nitrous oxide can cause detonation, where the fuel-air mixture ignites prematurely. This may result in melted pistons or damaged cylinder heads.

- Fuel System Requirements: A robust fuel system is essential to supply extra fuel for proper air-fuel ratios. Insufficient fuel delivery can lead to a lean condition and severe engine damage.

- Legal and Regulatory Concerns: Many regions regulate nitrous oxide systems in street vehicles for safety and environmental reasons. Always check and comply with local laws.

Safety Measures for Using Nitrous Oxide

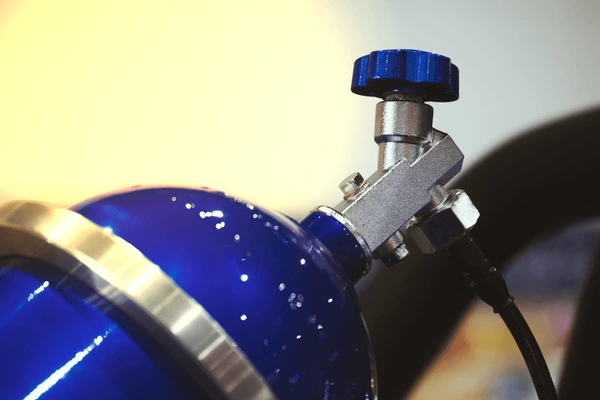

- Proper Installation: Installing the nitrous oxide system correctly is critical for safety. Use high-quality components, follow manufacturer guidelines, and ensure the intake manifold and injectors are properly aligned to prevent leaks.

- Controlled Usage: Use nitrous oxide carefully to avoid engine damage. Follow recommended N2O levels and confirm your engine can handle the power boost. Monitor air-fuel ratios, exhaust temperatures, and cylinder pressure to ensure safe operation.

- Regular Maintenance: Regularly inspect the system and engine components to ensure smooth performance. Check for leaks, examine hoses and injectors, and secure all connections to avoid malfunctions.

- Safety Devices: Install safety features like pressure relief valves, burst discs, and solenoids to prevent over-pressurization. These devices release excess pressure and protect the system from catastrophic failures.

Applications of Nitrous Oxide

Chemical and Catalytic Applications

Nitrous oxide serves as a powerful oxidant in gas and liquid-phase reactions, particularly in oxidation chemistry and catalysis. It plays a crucial role in organic synthesis and the catalytic decomposition of nitrogen oxides. Industries also use it for high- and low-temperature reduction processes with natural gas and ammonia.

Medical Applications

In healthcare, nitrous oxide is a widely used anesthetic and analgesic. It provides fast pain relief during dental procedures, minor surgeries, and neonatal care for persistent pulmonary hypertension. Its rapid onset and quick recovery make it ideal for medical use.

Rocket Propulsion

The aerospace industry uses nitrous oxide as an oxidizer in rocket propulsion systems. Its self-pressurizing properties, high density, and stable temperatures improve performance. Nytrox, a mixture of nitrous oxide and oxygen, enhances combustion efficiency and safety, making it valuable for long-term space missions.

Environmental Applications

Nitrous oxide is a potent greenhouse gas, especially from agricultural emissions. Advanced geochemical models like DNDC and DayCent help estimate and mitigate its release. Industries also use absorption and adsorption techniques to neutralize nitrogen oxides and reduce pollution.

Food Industry

In food production, nitrous oxide acts as a propellant in whipped cream dispensers and a foaming agent for packaging. Its non-toxic nature ensures safe and stable foaming, making it ideal for consumer products.

Industrial Applications

Industries use nitrous oxide in nitric acid production, semiconductor surface oxidation, and as a polymerization inhibitor for olefins. It also modifies polymer properties, further extending its industrial applications.

Emerging Applications

Research highlights nitrous oxide’s potential as a spacecraft propellant, delivering higher performance than traditional systems. Additionally, photolysis of nitrous oxide to produce nitric oxide opens possibilities for safer and more efficient medical inhalation therapies.

Latest Technical Innovations in Nitrous Oxide

Advancements in Production Processes

Recent research has highlighted significant improvements in the production of nitrous oxide, particularly focusing on efficiency and sustainability. Traditional methods involve the decomposition of ammonium nitrate, but new technologies are being developed to enhance this process.

- Catalytic Production: Innovations in catalytic systems have led to more efficient production methods. For instance, the development of new catalysts has improved the yield and purity of N2O, reducing the energy consumption and by-products associated with traditional methods.

- Alternative Raw Materials: Research is exploring the use of alternative raw materials to produce N2O. These methods aim to reduce the dependency on ammonium nitrate and minimize environmental impact.

Environmental Impact Reduction

Given the significant role of nitrous oxide as a greenhouse gas, recent advancements have focused on reducing its environmental footprint during production and use.

- Catalytic Decomposition: Advanced catalytic systems have been developed to decompose N2O more effectively. These systems achieve up to 80-90% decomposition efficiency, with ongoing research aimed at developing more active and stable catalysts to further increase this rate.

- Emission Control: New methods for controlling emissions during the production of nitric acid, a major industrial source of N2O, have been introduced. These include high- and low-temperature one-pot methods that significantly reduce N2O emissions.

Safety Measures and Handling Technology

Safety in the handling and storage of nitrous oxide is paramount due to its potential hazards. Recent advancements have focused on improving these aspects to ensure safer industrial practices.

- Self-Pressurizing Systems: The development of nitrous oxide and oxygen mixtures (Nytrox) has introduced a new class of oxidizers with enhanced safety features. These mixtures offer self-pressurization capabilities, non-cryogenic operational temperatures, and improved safety compared to pure oxidizers.

- Stable and Efficient Storage: Innovations in storage technology have led to more stable and efficient systems for handling N2O. These advancements include improved containment materials and methods to prevent accidental release and ensure long-term stability.

FAQ

What does nitrous oxide do in a car?

- It boosts engine performance by providing extra oxygen for combustion, resulting in increased horsepower.

Is nitrous oxide safe for cars?

- When properly installed and used responsibly, it can be safe, but improper use can damage the engine.

How does nitrous oxide compare to turbochargers?

- NOS provides instant power but requires refills, while turbochargers offer continuous performance boosts.

Can nitrous oxide in cars damage an engine?

- Overuse or improper tuning can cause engine stress, overheating, and potential damage.

Is using nitrous oxide in cars legal?

- Regulations vary; check local laws before installing or using NOS systems.

To get detailed scientific explanations of nitrous oxide in cars, try Patsnap Eureka.

Learn more

2024 Toyota Hilux Review: Everything You Need to Know

The LS3 Engine: Unleashing Power and Efficiency in Automobile

V12 Engine: Unleashing Ultimate Power, Performance, and Luxury