Technical Background and Objectives

Torque wrenches are essential tools used in various industries, including automotive, aerospace, and construction, to ensure proper tightening of fasteners to specified torque values. The ease of installation and use of these tools is crucial for efficient operations and worker safety. Over the years, torque wrenches have undergone several advancements to improve their functionality and user-friendliness.

The primary objective of this research is to explore innovative solutions that can further enhance the ease of installation and use of torque wrenches. This includes investigating ergonomic designs, intuitive user interfaces, and advanced features that can streamline the installation process, reduce the risk of errors, and improve overall productivity.

Despite the advancements in torque wrench technology, challenges remain in ensuring seamless installation and operation, particularly in complex or confined work environments. Factors such as accessibility, ergonomics, and user training can impact the overall ease of installation and use, leading to potential safety risks and productivity losses.

To get detailed scientific explanations of the easier torque wrenches, try Patsnap Eureka TechResearch.

Market Demand Analysis

The market demand for torque wrenches with improved ease of installation is driven by several factors across various industries:

- Automotive Industry: Efficient and accurate torque application is crucial for ensuring the proper assembly and maintenance of vehicles. Mechanics often work in confined spaces, making the installation and removal of torque wrenches challenging. Improved ease of installation can enhance productivity and reduce injury risks.

- Aerospace Industry: Precision and safety are paramount, with high demand for user-friendly torque wrenches. Aircraft maintenance technicians frequently work on intricate components in tight spaces, where easy-to-install tools streamline workflows and minimize errors.

- Oil and Gas Industry: With its complex machinery and equipment, this industry requires torque wrenches that can be easily installed and removed. Efficient tool handling contributes to cost savings and improved operational efficiency.

The growing emphasis on ergonomics and worker safety across various industries has increased the demand for torque wrenches designed with user comfort and ease of use in mind. Market research indicates that end-users are willing to invest in torque wrenches with improved ease of installation if they can demonstrate tangible benefits, such as increased productivity, reduced downtime, and enhanced worker safety.

Current State and Challenges

Challenges:

- Complexity of Calibration: Torque wrenches require precise calibration to ensure accurate torque measurements. The calibration process can be complex and time-consuming, often requiring specialized equipment and expertise.

- Compatibility Issues: Mismatched components or improper installation can lead to damage, inaccurate readings, or safety risks.

- Ergonomic Challenges: Bulky and heavy torque wrenches can be difficult to maneuver and install in tight spaces, leading to user fatigue, discomfort, and safety risks.

- Limited User Training: Proper installation and use often require specialized training. Inadequate training can lead to improper installation, misuse, or misinterpretation of readings.

- Environmental Factors: Extreme temperatures, moisture, or vibrations can affect torque wrench accuracy and performance.

- Geographic Distribution: Availability and accessibility of torque wrenches and the required expertise can vary across regions, creating challenges in ensuring consistent installation practices.

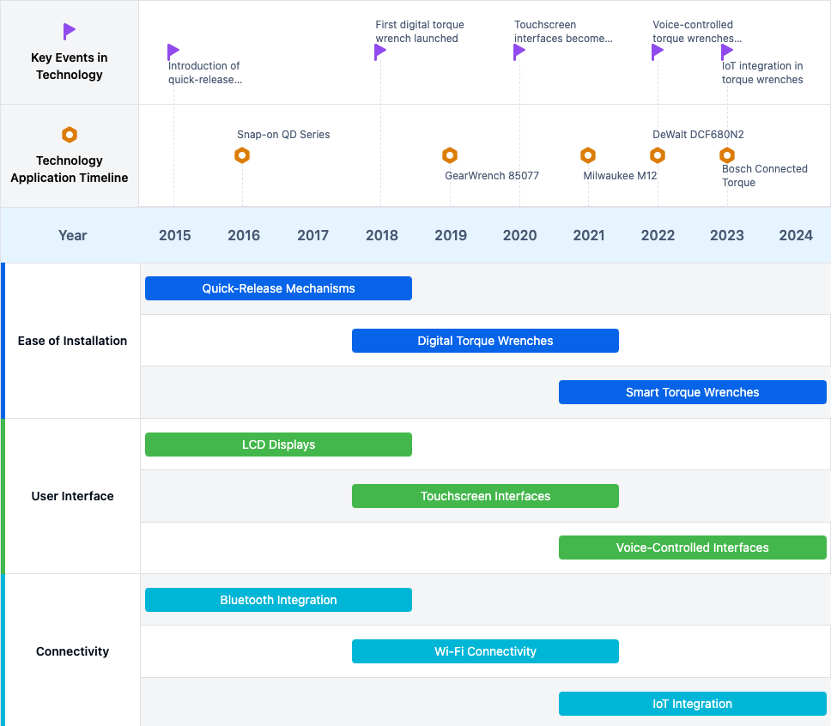

Technology Evolution Path

Current Technical Solutions

Torque Wrench Design and Structure:

- Adjustable Torque Settings: Mechanisms like dials, levers, or other components enable quick and precise setting of the desired torque level.

- Ergonomic Handles and Compact Designs: Designed to improve ease of use, especially in tight spaces.

Torque Wrench with Torque Indication or Feedback:

- Visual or Audible Feedback: Provides alerts when the desired torque level is reached, ensuring proper tightening.

Torque Wrench with Ergonomic or User-Friendly Design:

- Comfortable Grips and Lightweight Materials: Reduce user fatigue and improve control during use.

Torque Wrench Accessories and Attachments:

- Wrench Extenders and Adapters: Enhance ease of installation by improving accessibility in tight spaces.

Torque Wrench Control and Feedback Mechanisms:

- Real-Time Monitoring and Adjustment: Allows for precise torque application and prevents over-tightening or under-tightening.

Key Players Analysis

Hangzhou Perine Tools Co. Ltd.:

- Technology: Provides a torque wrench with a simplified calibration process, including a built-in calibration indicator.

Kabo Tool Company:

- Technology: Offers a lightweight and compact torque wrench designed for ease of transport and use in tight spaces.

Grip Holding AS:

- Technology: Introduced a torque wrench with an integrated LED light and audible alert system for accuracy and safety.

Milwaukee Electric Tool Corp.:

- Technology: Offers a torque wrench with a digital interface, intuitive display, and preset torque settings.

The Black & Decker Corp.:

- Technology: Developed a torque wrench with a quick-release mechanism and ergonomic handle design for faster and more comfortable installation.

Key Technology Interpretation

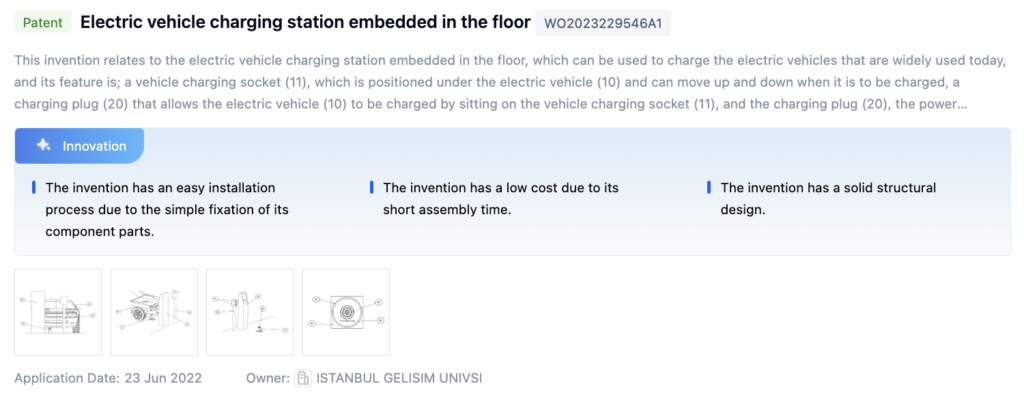

Patent 1: Electric Vehicle Charging Station Embedded in the Floor

- Core Points:

- Easy Installation: Simple fixation of component parts.

- Low Cost: Short assembly time.

- Solid Structural Design: Ensures durability.

Patent 2: Multipurpose and Universal Wrench

- Core Points:

- Correct Torque Application: Ensures precise tightening.

- Ease of Use: Designed to be folded for easy storage.

- Safety: Reduces risks associated with improper tightening.

Paper 1: High Precision Small Size and Flexible FBG Strain Sensor for Slope Model Monitoring

- Core Points:

- Low Cost: Affordable fabrication and installation.

- Ease of Application: Short operating time with simple installation.

- High Performance: Excellent reliability in use.

Potential Innovation Directions

Torque Wrench Design for Ease of Installation:

- Ergonomic Handles and Adjustable Head Angles: Improve access to tight spaces and ease of use.

Torque Wrench with Visual or Audible Feedback:

- Clear Feedback Mechanisms: Indicate when the desired torque is reached, simplifying the installation process.

Torque Wrench with Adjustable Torque Settings:

- Versatility in Installation: Allows adaptation to different torque requirements.

Torque Wrench with Extension or Adapter:

- Enhanced Accessibility: Improves reach in confined spaces.

Torque Wrench with Digital or Electronic Features:

- Advanced Features: Automatic torque setting, data logging, and wireless connectivity streamline installation processes.

Installation Ease Factors

Key factors influencing ease of installation include:

- Design: Ergonomic features like comfortable grips, balanced weight distribution, and easy-to-read scales enhance user experience and reduce fatigue.

- Compatibility: A versatile wrench accommodating various sockets and attachments reduces the need for frequent tool changes.

- Durability: High-quality materials and precise manufacturing minimize wear and calibration drift.

- Training and User Education: Proper training and user education are crucial for maximizing ease of installation and reducing errors.

- Digital Integration: Wireless connectivity and data logging capabilities enable remote monitoring and automated processes, further enhancing ease of installation.

User Experience and Feedback

Gathering user feedback through surveys, focus groups, or field observations provides valuable insights into the challenges faced by technicians during installation. Redesigning tools to improve grip, maneuverability, and feedback mechanisms can enhance the user experience. Advanced technologies like augmented reality (AR) or virtual reality (VR) can offer interactive guidance, reducing errors and improving efficiency.

Engaging with end-users throughout the development process ensures that proposed solutions effectively address pain points, leading to more intuitive and user-friendly tools.

If you want in-depth research or a technical report, you can always get what you want in Patsnap Eureka TechResearch. Try now!