Nichrome, a nickel-chromium alloy, is best known for its outstanding heat resistance and electrical conductivity. It’s a staple in high-temperature environments, electric heating elements, and precision instruments due to its stability and durability. As industries pivot toward smarter, more energy-efficient systems, Nichrome’s multifaceted utility continues to grow.

This article examines Nichrome’s composition and key material properties, followed by a categorized overview of its major industrial applications. We’ll also discuss its advantages and limitations, emerging research directions, and how tools like PatSnap Eureka AI Agent can accelerate innovation with Nichrome.

Material Composition & Key Properties

- Primary Composition: Typically 80% nickel and 20% chromium

- Melting Point: Around 1400°C

- Electrical Resistivity: ~1.10 µΩ·m

- Key Features:

- High-temperature resistance

- Strong oxidation resistance

- Moderate tensile strength and flexibility

- Stable resistivity over time

- Common Forms: Wire, ribbon, strip, rod

- Preparation Method: Melt-casting followed by cold working

Application Domains

High-Temperature Applications

Nichrome’s ability to retain its structure and resist oxidation at high temperatures makes it ideal for heating systems. It supports everything from small appliances to industrial furnaces.

Related Reports:

- Nichrome Applications in High-Temperature Wire Alloys

- Future Trends in Nichrome for Heating Elements

- How to Maximize Efficiency in Nichrome Heating Coils?

- Advanced Nichrome Alloys for Industrial Furnace Systems

- Nichrome Uses in Modern Electric Oven Designs

- Enhancing Durability of Nichrome Heating Elements

- How Nichrome Supports Long-Lasting Heating Devices?

Electrical and Sensing Devices

From resistors to modern sensors, Nichrome’s stable resistivity and low thermal drift are invaluable. It ensures accurate signal transmission and thermal sensing even under fluctuating conditions.

Related Reports:

- Nichrome Wire Applications in Precision Resistors

- Advanced Nichrome Types for Electrical Insulation

- Nichrome’s Role in Improving Electrical Conductivity

- Nichrome and Its Applications in Precise Temperature Sensors

- How Nichrome Wire Supports Precision Measurement Devices?

- Nichrome Wire Advancements in Precision Engineering

- Benefits of Nichrome in Modern Semiconductor Manufacturing

Material Stability and Corrosion Resistance

Nichrome’s chromium content forms a passive oxide layer, reducing oxidation and chemical degradation, making it ideal for demanding environments like marine, chemical, and lab systems.

Related Reports:

- Enhancing Corrosion Resistance in Nichrome Alloys

- How to Reduce Oxidation in Nichrome Elements?

- How to Optimize Nichrome Alloy Composition?

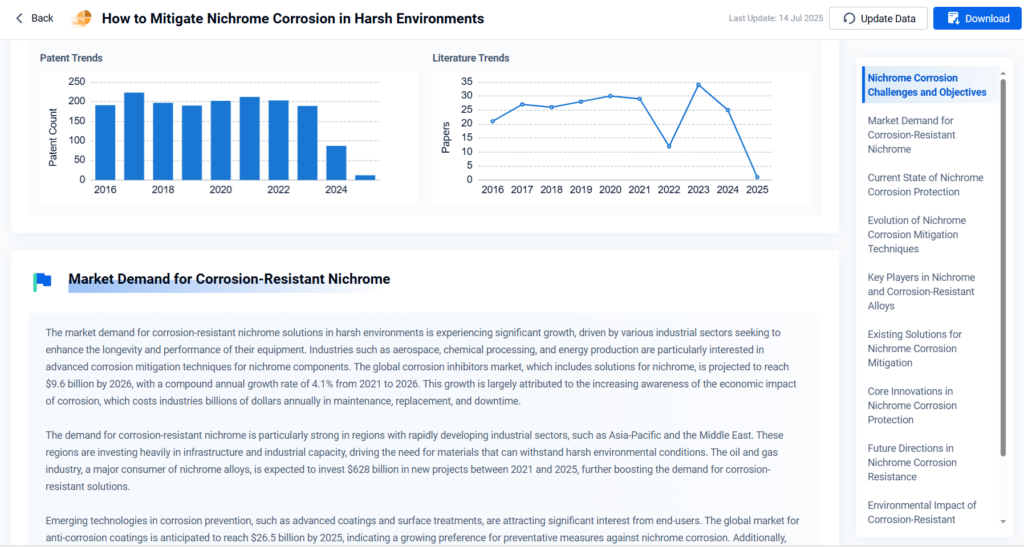

- How to Mitigate Nichrome Corrosion in Harsh Environments?

- How to Enhance Nichrome’s Properties for Emerging Industries?

- How to Address Nichrome’s Limitations in High-Stress Environments?

- Nichrome in High-Temperature Lab Equipment

Sustainable and Smart Energy Systems

Nichrome is essential to the development of energy-efficient systems, from solar heating to smart appliances. Its controllable heating properties align well with renewable tech trends.

Related Reports:

- Leveraging Nichrome in Renewable Energy Systems

- Nichrome’s Contribution to Energy-Efficient Appliances

- How to Improve Nichrome’s Efficiency in Solar Panels?

- Nichrome’s Impact on the Next Generation of Fuel Cells

- Nichrome in Renewable Technologies: Driving Energy Efficiency

- Nichrome and Its Future Role in Green Technology

- Nichrome Applications in Sustainable Energy Development

Aerospace and Transportation

In aviation and modern transit systems, Nichrome is utilized for insulation, thermal control, and heating. Its lightweight and stable nature is critical for harsh aerospace environments.

Related Reports:

- How to Incorporate Nichrome in Aerospace Engineering?

- Nichrome Wire for Advanced Aerospace Insulation

- Nichrome Use Cases in Spacecraft Engineering

- The Role of Nichrome in Enhancing Aerospace Detection Systems

- How to Select Nichrome Alloys for Aerospace Applications?

- Nichrome Wire Applications in High-Speed Rail Systems

- Nichrome’s Growing Importance in Electric Vehicle Technology

Emerging Technologies and Cross-Industry Use

Nichrome’s adaptability has driven innovation in biotech, smart cities, 3D printing, AI devices, and wearable tech, redefining what thermal and conductive materials can achieve.

Related Reports:

- Nichrome in 3D Printing: Exploring Thermal Applications

- Exploring Nichrome’s Applications in Medical Devices

- Nichrome in Biotech: Innovation in Thermal Regulation Devices

- Nichrome and Its Future in Smart Heating Technologies

- The Future of Nichrome in IoT-Enabled Devices

- Nichrome Wire’s Application in IoT Device Innovation

- Nichrome for Modern AI Equipment Heating Solutions

Comparative Advantages & Limitations

| Feature | ✓ Advantage | Limitation |

|---|---|---|

| Heat resistance | Maintains performance up to ~1400°C | Brittle at extremely high temps |

| Electrical resistivity | Predictable and stable | Less conductive than pure metals |

| Corrosion resistance | Self-passivating oxide layer | Surface may degrade in strong acids |

| Versatility | Suitable for wire, coil, ribbon, etc. | Limited elasticity |

| Cost-effectiveness | Low maintenance, long lifecycle | Higher cost than cheaper alloys |

Future Outlook & Research Frontiers

Nichrome is undergoing a resurgence in high-tech fields thanks to its integration with IoT, AI, and clean energy systems. Future research is focused on improving its oxidation resistance and integrating nanotechnology to enhance thermal precision.

Key Trends Ahead:

- AI-optimized heating elements

- Nichrome coatings for advanced fuel cells

- Low-carbon manufacturing of Nichrome wires

- Additive manufacturing with Nichrome-infused powders

- Thermal regulation layers in spacecraft and drones

- Nichrome-based microheaters in bio-MEMS sensors

Conclusion &Key Takeaways

Nichrome stands at the intersection of thermal durability and electric precision. Its unique balance of resistivity and environmental resilience enables a broad spectrum of applications—from aerospace to everyday appliances. As materials science advances, Nichrome remains a foundational alloy for the future of smart, efficient systems.

Accelerate Innovation with PatSnap Eureka AI Agent

Ready to unlock the full potential of Nichrome?

PatSnap Eureka AI Agent empowers your R&D team to explore untapped white spaces, visualize patent landscapes, and benchmark competitor innovations—all in one platform.