Introduction

Understanding the differences between convection vs. conventional ovens is crucial when selecting the right appliance for your kitchen. Both types cater to unique cooking needs, with convection ovens offering faster, more even cooking through fan-driven hot air circulation, while conventional ovens rely on natural air flow for heat distribution. Recent advancements in oven technology fueled by research and development have improved efficiency, performance, and versatility in both designs. This article delves into the features, benefits, and innovations of convection and conventional ovens, helping you choose the best option for your cooking style.

What are Convection Ovens?

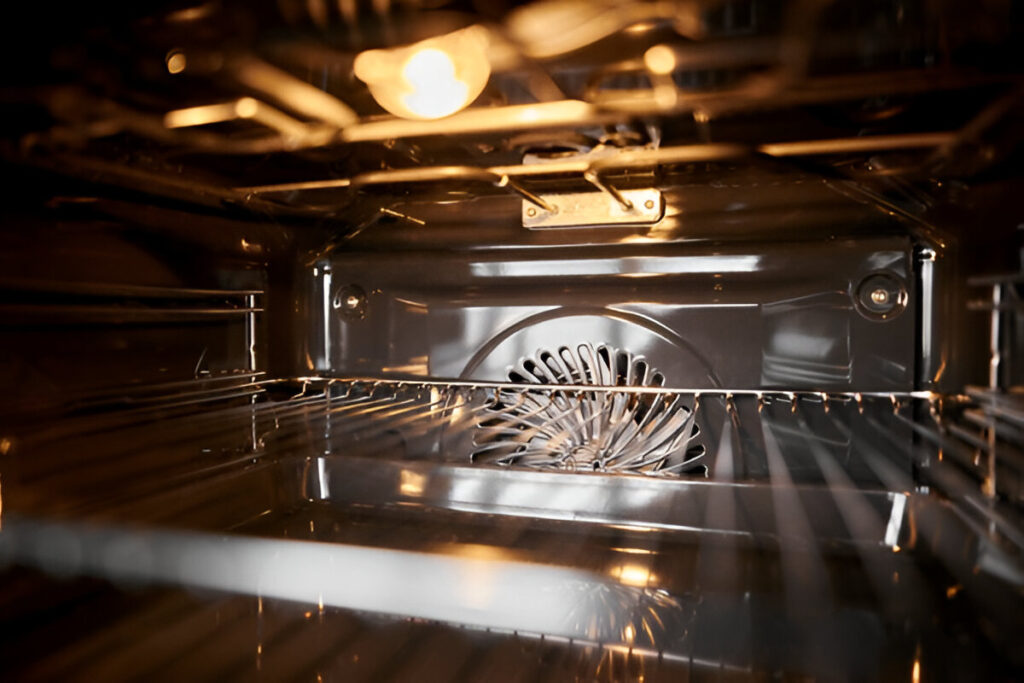

Convection ovens are a type of oven that use fans to circulate hot air around the food, providing more even cooking and often reducing cooking times compared to traditional ovens. This technology is widely used in both domestic and industrial settings for various cooking and baking applications.

Core Components and Working Principles

Convection ovens operate by circulating hot air around the food or product being heated, ensuring even cooking or processing.

- Control System: Manages temperature, airflow, and other parameters to maintain optimal conditions for the specific application.

- Heating Element: Generates the necessary heat, often through electric coils or fuel burners. For instance, a convection oven may include a fuel burner that indirectly heats an oven chamber through a heat exchange interface.

- Air Circulator: A fan or blower that circulates the hot air throughout the oven chamber. This ensures uniform temperature distribution and efficient heat transfer.

- Heat Exchanger: Transfers heat from the heating element to the circulating air. Some designs incorporate linear counter-flow heat exchangers, where process air flows in one direction and the heated fluid flows in the opposite direction, maximizing heat transfer efficiency.

What are Conventional Ovens?

A conventional oven is a kitchen appliance used for cooking or heating food. Modern conventional ovens are typically fueled by either natural gas or electricity and are often integrated into a kitchen stove, which has a top surface with pre-defined burners for placing cooking pans. Conventional ovens usually include a heating element located below the food, supported on a rack within the oven cavity. Some modern versions also incorporate a top heating element for broiling purposes.

Core Components and Working Principles

- Heating Elements: Conventional ovens generally include a bottom heating element and may also feature a top heating element for broiling.

- Air Circulation: The introduction of fans in the 1960s allowed for air circulation, improving cooking efficiency by convection.

- Size and Space Utilization: Conventional ovens are often larger than necessary for most cooking tasks, leading to inefficiencies in space utilization.

- Cleaning Challenges: These ovens are typically difficult to clean due to their size and design.

Convection Oven vs. Conventional Oven: Key Differences

Heat Transfer Mechanisms

- Conventional Ovens: These ovens primarily use radiant heat from heating elements such as bake and broil elements. Heat is transferred by radiation from the walls of the oven cavity or by natural convection, where hot air rises and circulates naturally within the oven.

- Convection Ovens: These ovens utilize a fan to circulate hot air uniformly throughout the oven cavity. This forced convection mechanism enhances heat transfer efficiency, leading to more uniform cooking and reduced cooking times.

Energy Efficiency and Heat Distribution

- Conventional Ovens: Heat distribution can be uneven due to reliance on natural convection and radiant heat. This often results in hot spots and requires more energy to maintain consistent temperatures across the cooking chamber.

- Convection Ovens: The use of a fan to circulate air ensures even heat distribution, reducing energy consumption and cooking times. This method also minimizes heat loss and improves overall cooking efficiency.

Cooking Performance and Versatility

- Conventional Ovens: These ovens are suitable for a wide range of cooking tasks but may struggle with uniformity, especially for items like bread that require consistent heat for proper baking.

- Convection Ovens: They offer superior performance for tasks requiring uniform heat, such as baking and roasting. The ability to control the fan speed and direction further enhances cooking versatility, allowing for precise temperature control and improved food quality.

Technological Innovations

- Conventional Ovens: Innovations are typically focused on improving the efficiency of radiant heating elements and incorporating additional cooking modes like microwave or steam to enhance versatility.

- Convection Ovens: Recent advancements include features like variable-speed, reversible blowers, vapor collection systems, and programmable controllers. These innovations aim to improve cooking uniformity, reduce energy consumption, and enhance user convenience.

User Interface and Control Systems

- Conventional Ovens: Generally feature simpler control interfaces, often limited to temperature and timer settings. This simplicity can be advantageous for users who prefer straightforward operation.

- Convection Ovens: Often equipped with advanced control systems, including touch screens and programmable settings. These interfaces allow users to customize cooking parameters precisely, taking full advantage of the oven’s capabilities.

Maintenance and Accessibility

- Conventional Ovens: Maintenance can be cumbersome due to the need to disassemble parts to access electrical components. This can lead to higher service costs and downtime.

- Convection Ovens: Designed with maintenance in mind, these ovens often feature easily accessible electrical components and self-cleaning systems. This reduces service time and improves overall reliability.

Applications in Product Development

- Conventional Ovens: Suitable for general cooking applications but may require additional features or modifications to meet specific product development needs, such as combining with other cooking technologies.

- Convection Ovens: Ideal for product development scenarios that demand precise temperature control and uniform cooking. Their versatility and advanced features make them suitable for developing a wide range of food products, from baked goods to roasted meats.

FAQ

Which oven is better for baking: convection or conventional?

- Convection ovens are ideal for baking pastries and cookies due to their even heat distribution. However, for delicate items like souffles or cakes that require rising, a conventional oven may be preferable to prevent the batter from setting too quickly.

Can you use aluminum foil in a convection oven?

- Yes, you can use aluminum foil in a convection oven. However, it’s important not to cover the oven’s racks or obstruct the fan, as this can interfere with air circulation and cooking performance.

To get detailed scientific explanations of Convection vs. Conventional Ovens, try Patsnap Eureka.