What is a Clutch Slave Cylinder?

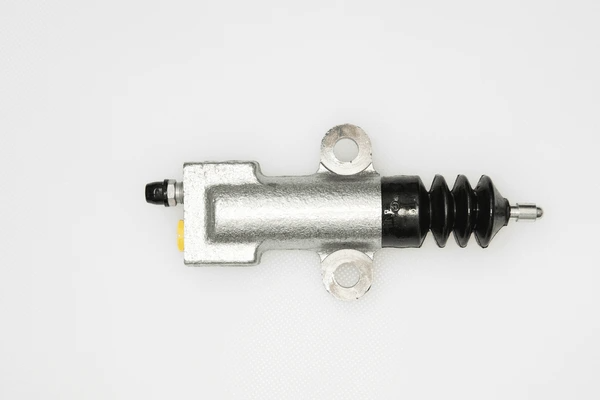

A clutch slave cylinder is a critical component in the hydraulic clutch system of a vehicle. It is responsible for engaging and disengaging the clutch by converting hydraulic pressure from the master cylinder into mechanical force. This mechanical force then acts on the clutch release bearing, which in turn engages or disengages the clutch.

Key Components

- Cylinder Housing: The housing of the slave cylinder includes a longitudinal bore to receive the transmission input shaft and forms a pressure chamber situated concentrically to the longitudinal bore.

- Piston: The piston is guided axially within the housing and is responsible for actuating the clutch release bearing. It is typically pre-tensioned with respect to the slave cylinder housing by means of a preloading spring.

- Pressure Chamber: The pressure chamber is where hydraulic fluid from the master cylinder is received, creating the necessary force to move the piston.

- Release Bearing: The release bearing is connected to the piston and is responsible for engaging and disengaging the clutch. It is often protected by a bellows to prevent contamination.

How Does a Clutch Slave Cylinder Work?

The hydraulic mechanism of a clutch slave cylinder operates by receiving hydraulic fluid from the master cylinder. When the clutch pedal is pressed, hydraulic fluid is forced into the slave cylinder’s pressure chamber. This pressure moves the piston axially, which in turn moves the clutch release bearing. The movement of the release bearing engages or disengages the clutch, allowing for smooth gear changes.

Signs of a Failing Clutch Slave Cylinder

- Difficulty Shifting Gears: If the slave cylinder fails, it may not generate enough pressure to disengage the clutch fully, making it hard to shift gears.

- Spongy or Soft Clutch Pedal: A failing slave cylinder can cause a loss of hydraulic pressure, resulting in a spongy or soft clutch pedal feel.

- Clutch Pedal Stays on the Floor: In severe cases, the clutch pedal may not return to its original position after being depressed.

- Fluid Leaks: Hydraulic fluid leaks around the slave cylinder or on the ground under the vehicle can indicate a failing seal or damaged cylinder.

- Unusual Noises: Grinding or squeaking noises when pressing the clutch pedal can be a sign of internal damage or wear within the slave cylinder.

Common Issues and Troubleshooting

- Hydraulic Fluid Leaks: Inspect the slave cylinder and surrounding areas for signs of hydraulic fluid leaks. If leaks are found, the seals or the entire slave cylinder may need to be replaced.

- Air in the Hydraulic System: Air trapped in the hydraulic system can cause a spongy clutch pedal. Bleeding the clutch system to remove air can restore proper function.

- Worn or Damaged Seals: Over time, the seals within the slave cylinder can wear out or become damaged, leading to fluid leaks and loss of pressure. Replacing the seals or the entire slave cylinder can resolve this issue.

- Contaminated Hydraulic Fluid: Dirt or debris in the hydraulic fluid can cause blockages and impair the function of the slave cylinder. Flushing and replacing the hydraulic fluid can help maintain proper operation.

- Mechanical Wear: Components such as the piston or housing can wear out over time, leading to poor performance. Inspecting and replacing worn parts can restore functionality.

Maintenance Tips for Clutch Slave Cylinders

- Regular Inspection: Periodically inspect the clutch slave cylinder and the hydraulic system for signs of wear, leaks, and contamination.

- Fluid Replacement: Replace the hydraulic fluid at regular intervals to ensure it remains clean and free of contaminants. This helps maintain the performance and longevity of the hydraulic system.

- Seal Maintenance: Check the condition of the seals and replace them if they show signs of wear or damage. Using high-quality seals can improve the durability of the slave cylinder.

- Protect from Corrosion: Ensure that the slave cylinder and hydraulic lines are protected from moisture and corrosive elements. Applying a protective coating can help prevent corrosion.

Replacement and Costs

Replacement

- Lift the Vehicle: Safely lift and support the vehicle to access the slave cylinder.

- Remove Hydraulic Lines: Disconnect the hydraulic lines from the slave cylinder, taking care to catch any leaking fluid.

- Unbolt the Slave Cylinder: Remove the bolts securing the slave cylinder to the transmission.

- Install the New Cylinder: Position the new slave cylinder and secure it with bolts. Reconnect the hydraulic lines.

- Bleed the System: Bleed the hydraulic system to remove any air and ensure proper operation.

- Test the Clutch: Test the clutch pedal for proper operation and check for any leaks.

Costs

The cost of replacing a clutch slave cylinder can vary depending on the vehicle make and model, labor rates, and the cost of parts. On average, the cost can range from $150 to $300 for parts and labor. High-end or specialty vehicles may incur higher costs due to more expensive parts and additional labor required for access and installation.

Advantages of a Well-Maintained Clutch Slave Cylinder

Enhanced Performance and Efficiency

- Smooth Operation: A well-maintained slave cylinder ensures smooth engagement and disengagement of the clutch, leading to a more responsive and efficient driving experience. This is achieved by maintaining the integrity of the hydraulic system, which minimizes friction and wear on the clutch components.

- Consistent Pressure: Proper maintenance ensures that the hydraulic pressure within the slave cylinder remains consistent, which is essential for the accurate operation of the clutch. This consistency helps in maintaining the correct pressure plate position, thereby improving the overall performance of the clutch system.

Increased Longevity and Reliability

- Reduced Wear and Tear: Regular maintenance helps in reducing the wear on the seals and the piston within the slave cylinder. This is particularly important as the seals are responsible for maintaining the hydraulic pressure and preventing leaks. By reducing wear, the lifespan of the slave cylinder and the clutch system as a whole is extended.

- Prevention of Failures: Regular inspections and maintenance can help in identifying potential issues before they lead to failures. This proactive approach ensures that the clutch system remains reliable and reduces the likelihood of unexpected breakdowns.

Cost-Effectiveness

- Lower Maintenance Costs: By maintaining the slave cylinder in good condition, the need for frequent repairs and replacements is minimized. This not only reduces the overall maintenance costs but also ensures that the vehicle remains operational for longer periods without requiring major interventions.

- Extended Component Life: Proper maintenance extends the life of not just the slave cylinder but also other related components such as the clutch master cylinder and the clutch disc. This holistic approach to maintenance ensures that all components work harmoniously, thereby reducing the overall cost of ownership.

Improved Safety

- Reliable Clutch Engagement: A well-maintained slave cylinder ensures that the clutch engages and disengages reliably, which is crucial for safe driving. This reliability is particularly important in situations that require precise control of the vehicle, such as during gear changes or when navigating through traffic.

- Prevention of Hydraulic Leaks: Regular maintenance helps in preventing hydraulic leaks, which can compromise the performance of the clutch system and lead to safety hazards. Ensuring that the hydraulic system is leak-free is essential for maintaining the integrity of the clutch operation.

Optimized Performance in Various Conditions

- Adaptability to Different Driving Conditions: A well-maintained slave cylinder can adapt to various driving conditions, including high temperatures and heavy loads. This adaptability ensures that the clutch system performs optimally regardless of the driving environment.

- Enhanced Flexibility: Modern slave cylinders are designed to offer flexibility in terms of installation and operation. For instance, some designs allow for adjustable pressure plates, which can be beneficial in fine-tuning the clutch performance to suit specific driving needs.

Comparison with Clutch Master Cylinder

Design Structure

- Hydraulic Clutch Master Cylinder: This type typically includes a piston connected to the clutch pedal, which generates hydraulic pressure to operate the clutch. The structure often involves a cylinder, piston, return spring, and valve assembly.

- CCF (Controlled Clutch Forces) System: This design reduces pedal force and compensates for clutch disk wear, enhancing ergonomics and convenience.

- Air Breathing Performance: Some designs focus on improving air bleeding efficiency, reducing the time required for air bleeding work.

Materials Used

- Aluminum vs. Plastic: Aluminum master cylinders are traditional, but plastic variants offer benefits such as modularity, lightweight, and better NVH (Noise, Vibration, Harshness) performance. Plastic master cylinders also simplify structure, reduce maintenance costs, and are environmentally friendly due to superior recyclability.

Hydraulic Efficiency

- Pressure Generation and Control: The ability to generate and control hydraulic pressure is crucial. Some designs include relief valves to maintain pressure within set limits, ensuring consistent performance.

- Sealing Performance: Innovations in sealing technology, such as using differential pressure sensors, improve the accuracy and speed of leak detection, enhancing overall reliability.

Automotive Industry

- Passenger Vehicles: Most innovations in clutch master cylinders are aimed at improving the driving experience in passenger vehicles, focusing on reducing pedal force and enhancing reliability.

- Commercial Vehicles: For commercial vehicles, especially those with heavy-duty requirements, air power-assisted master cylinders provide significant benefits in terms of reducing driver fatigue and improving control.

Pedal Force and Ergonomics

- Pedal Force Reduction: Systems like the CCF master cylinder significantly reduce the pedal force required, making the clutch operation smoother and more ergonomic.

- Ergonomic Design: The design of the master cylinder can impact the driver’s comfort. Features like adjustable pedal force characteristics allow for optimized ergonomics.

Applications of Clutch Slave Cylinder

Automotive Industry

- Passenger Vehicles: In passenger cars, the clutch slave cylinder is used to disengage the clutch when the driver presses the clutch pedal. This allows for smooth gear changes and prevents the engine from stalling during stops. The concentric slave cylinder (CSC) is a common type used in modern vehicles due to its compact design and efficient operation.

- Commercial Vehicles: For trucks and buses, the clutch slave cylinder must handle higher loads and more frequent use. These vehicles often use robust slave cylinders with enhanced durability and heat resistance to withstand the demanding conditions.

- High-Performance and Racing Cars: In high-performance vehicles, the clutch slave cylinder is designed for quick and precise actuation to facilitate rapid gear shifts. These systems often incorporate advanced materials and designs to reduce weight and improve response times.

Motorcycles

- Motorcycles use clutch slave cylinders to manage the clutch engagement, allowing riders to shift gears smoothly. The design is typically more compact and lightweight compared to automotive applications, but it must still provide reliable performance under varying conditions.

Heavy Machinery

- Construction Equipment: In construction machinery such as excavators and loaders, clutch slave cylinders are used to control the power transmission systems. These cylinders must be highly durable and capable of operating in harsh environments with significant dust, dirt, and temperature variations.

- Agricultural Machinery: Tractors and other agricultural equipment use clutch slave cylinders to manage the power take-off (PTO) and transmission systems. These applications require cylinders that can handle high torque loads and provide consistent performance over long periods of use.

Industrial Applications

- Manufacturing Equipment: In industrial machinery, clutch slave cylinders are used in various automated systems where precise control of mechanical movements is required. These cylinders must offer high reliability and low maintenance to ensure continuous operation.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Concentric Slave Cylinder (CSC) Schaeffler Technologies AG & Co. KG | Compact design, efficient operation, and improved flexibility with anti-rotation device and support plate for axial adjustment. | Passenger vehicles for smooth gear changes and preventing engine stalling during stops. |

| Clutch Slave Cylinder Luk Lamellen & Kupplungsbau | Improves flexibility and reduces high cost and trouble associated with traditional designs. | General automotive applications requiring reliable clutch actuation. |

| Slave Cylinder for Clutch Mechanism Autoliv Nissin Brake Systems Japan Co Ltd | Allows change in connection direction of pipeline, improving layout flexibility. | Commercial vehicles requiring robust and flexible clutch systems. |

| Easy-to-Vent Clutch Slave Cylinder Wuhu Hengkun AUTO PARTS Co., Ltd. | Solves issues of tediousness and poor exhaust effect, improving maintenance efficiency. | Automotive systems where easy maintenance and efficient exhaust are critical. |

| Hydraulic Clutch Slave Cylinder Schaeffler Technologies AG & Co. KG | Features an annular pressure chamber and composite seal for enhanced sealing and durability. | High-performance and racing cars requiring quick and precise clutch actuation. |

Latest Technical Innovations in Clutch Slave Cylinder

Design Improvements

- Dual Annular Piston Design: A new clutch slave cylinder design uses two annular pistons, each in separate pressure chambers. It incorporates angular contact ball bearings and needle bearings for improved efficiency and durability.

- Height Adjustable Piston: A height-adjustable piston has also been developed for slave cylinders. This allows the piston to occupy different axial lengths, optimizing clutch or brake system operation.

Material Advancements

- Use of Rigid Plastic Materials: Advances in material science have led to using rigid plastic for the clutch slave cylinder cover. This simplifies construction, reduces costs, and makes detachment easier without damage.

- Composite Seals: Composite seals have also improved clutch slave cylinder performance. These seals use materials with distinct properties, such as combining one material for the first sealing element and another for the second, boosting sealing effectiveness and durability.

Manufacturing Techniques

- Simplified Mold Design: Recent advancements focus on simplifying mold designs for clutch slave cylinders. Attaching the stopper to the outer surface of the cylinder eliminates additional development of the inner surface, making mold separation smoother and cutting manufacturing costs.

- Easy-to-Vent Design: An improved clutch slave cylinder design addresses venting issues, featuring an injector device and an exhaust hole with a cylindrical air nozzle. This enables a more efficient and straightforward venting process, reducing steps and improving usability.

Functional Enhancements

- Dirt Protection: To enhance clutch slave cylinder reliability, recent innovations include a dirt guard designed as part of the housing. This guard prevents dirt from interfering with the release bearing and other components.

- Wear Adjustment Mechanism: A new clutch slave cylinder design features an adjustment piston separate from the release piston. This mechanism adjusts for clutch disc wear, maintaining consistent performance and reducing maintenance frequency.

To get detailed scientific explanations of clutch slave cylinders, try Patsnap Eureka.

Learn more

Shock Cords: Versatile Strength for Every Need

Pressure Switches: Small Devices, Big Impact

Unveiling The Lead Screw: Its Mechanism, Benefits, And Beyond