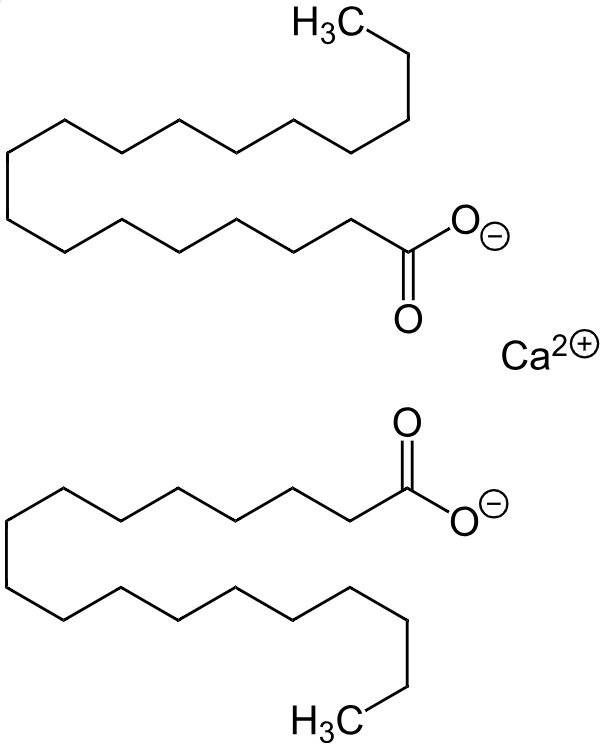

Calcium stearate is a white, waxy powder made from stearic acid and calcium oxide. As a calcium-based metallic soap, it delivers excellent lubricating, anti-caking, and water-repellent properties. These features make it an essential additive in numerous industries, including plastics, rubber, cosmetics, pharmaceuticals, and construction. This article explains how calcium stearate works, where it is most commonly used, and why it continues to be a preferred material in both industrial and consumer applications.

What Is Calcium Stearate?

What is calcium stearate? Eureka Technical Q&A explains this versatile compound used as a lubricant, stabilizer, and release agent in plastics, pharmaceuticals, and food processing, highlighting its non-toxic nature and wide industrial applications.

Calcium stearate is a calcium salt of stearic acid. It has a powdery texture, is insoluble in water, and offers stability in heat and chemical exposure. Unlike coatings or complex chemical treatments, its functions as a simple yet effective additive in manufacturing and processing systems.

Major Industrial Uses of Calcium Stearate

1. Plastic and Polymer Production

Manufacturers rely on calcium stearate to improve the processing of thermoplastics like PVC and polyethylene. It acts as an internal lubricant, reducing friction and preventing sticking during molding and extrusion.

Why it matters:

- Enhances mold release without additional coatings

- Decreases tool wear during high-speed production

- Helps stabilize heat-sensitive polymers

Moreover, when combined with other metal soaps like zinc stearate, it improves thermal stability in plastic formulations.

2. Rubber Manufacturing

In rubber production, calcium stearate serves as a mold release agent and processing stabilizer. It prevents premature curing, known as scorch, and improves filler dispersion.

Key advantages include:

- Cleaner separation from molds

- Better compound flow

- Neutralization of acidic ingredients during mixing

Because of these benefits, it is widely used in tires, seals, hoses, and rubber belts.

3. Construction and Cement Products

Calcium stearate is a common additive in concrete, mortar, and plaster. It increases water resistance and reduces efflorescence, which appears as white salt deposits on surfaces.

Application benefits:

- Repels moisture in cement-based materials

- Enhances durability in outdoor and humid conditions

- Minimizes surface staining and chalking

As a result, it helps maintain the appearance and structural integrity of buildings over time.

4. Cosmetics and Personal Care

Cosmetic chemists use calcium stearate in powders, creams, and pressed foundations. It functions as a thickener, texture enhancer, and anti-caking agent.

Why it’s included:

- Provides a silky, smooth feel

- Improves product flow in compacts

- Helps absorb skin oils for matte finishes

Its low toxicity and non-irritating nature make it suitable for sensitive skin products.

5. Food Industry

Calcium stearate is approved as a food-grade additive. In powdered foods and seasonings, it prevents clumping and ensures even flow during packaging and processing.

Common uses include:

- Preventing clumps in table salt and powdered milk

- Enhancing consistency in baking powders

- Stabilizing texture in dietary supplements

Because it’s chemically stable and non-toxic, it’s safe for use in regulated food applications.

6. Pharmaceutical Manufacturing

Tablet makers use calcium stearate as a flow agent and lubricant. It helps powders compress into tablets and reduces friction during pressing.

Why pharmaceutical companies use it:

- Ensures uniform tablet weight and density

- Prevents sticking to dies and punches

- Improves manufacturing efficiency

Its consistent performance supports large-scale production in pharmaceutical plants.

Cement Industry: Liquid calcium stearate is used to prevent secondary efflorescence and minimize the loss of solvated salts in concrete .

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| PVC Stabilizer China Petroleum & Chemical Corporation | Acts as heat stabilizer and lubricant in PVC production, improving thermal stability and processing. | PVC manufacturing and processing for various plastic products. |

| Precoated Sand Nanyang Renchuang Sand Industry Technology Co., Ltd | Enhances fluidity and compactness of castings, improves surface smoothness and thermal toughness. | Metal casting industry for producing high-quality molds and cores. |

| Pharmaceutical Formulations Glaxo Group Ltd. | Reduces chemical interactions with carriers, enhancing stability and shelf-life of active ingredients. | Drug formulation and manufacturing for improved medication stability. |

| High Solids Calcium Stearate Dispersion PPG Industries, Inc. | Improves rheological properties and compatibility in aqueous dispersions without urea. | Paper coating applications requiring high-performance additives. |

| ENR 25 Vulcanizates Chinese Academy of Tropical Agricultural Sciences | Enhances crosslink density, physical-mechanical properties, and thermal stability of epoxidized natural rubber. | Production of high-performance rubber products with improved aging resistance. |

Properties That Make Calcium Stearate Valuable

Calcium stearate is prized for its multifunctional properties that make it suitable for a broad range of industries. Its excellent lubricating ability reduces friction between surfaces during manufacturing, improving efficiency and equipment lifespan. The compound’s thermal stability ensures consistent performance at high processing temperatures, especially in plastics and rubber production. Its water-repellent nature makes it ideal for construction materials that require moisture resistance, such as cement and plaster. Additionally, calcium stearate is non-toxic and chemically inert, which allows for safe use in food, pharmaceuticals, and cosmetics. These combined features make it a dependable and adaptable additive in both industrial and consumer applications.

| Property | Functional Advantage |

|---|---|

| Water resistance | Prevents moisture absorption |

| Thermal stability | Performs well under high temperatures |

| Non-toxicity | Safe for food and pharmaceutical use |

| Lubrication | Reduces friction during processing |

| Compatibility | Works with plastics, rubbers, and more |

Environmental and Safety Profile

Calcium stearate is generally recognized as safe (GRAS) for human use. It does not introduce heavy metals or hazardous compounds. Additionally, it biodegrades over time and does not accumulate in the environment. However, manufacturers should avoid excessive inhalation of fine powders during processing.

Market Trends

The global calcium stearate market is expected to grow at a CAGR of around 5% from 2021 to 2026, driven by its wide range of applications and the increasing focus on efficiency and sustainability in chemical manufacturing . The market is projected to reach US$1.9 Billion by 2030 .

Research and Development

Investments in R&D are driving innovations in calcium stearate-based applications, and the market is seeing the emergence of new products with enhanced properties . The focus on sustainable production methods is also contributing to the market’s growth .

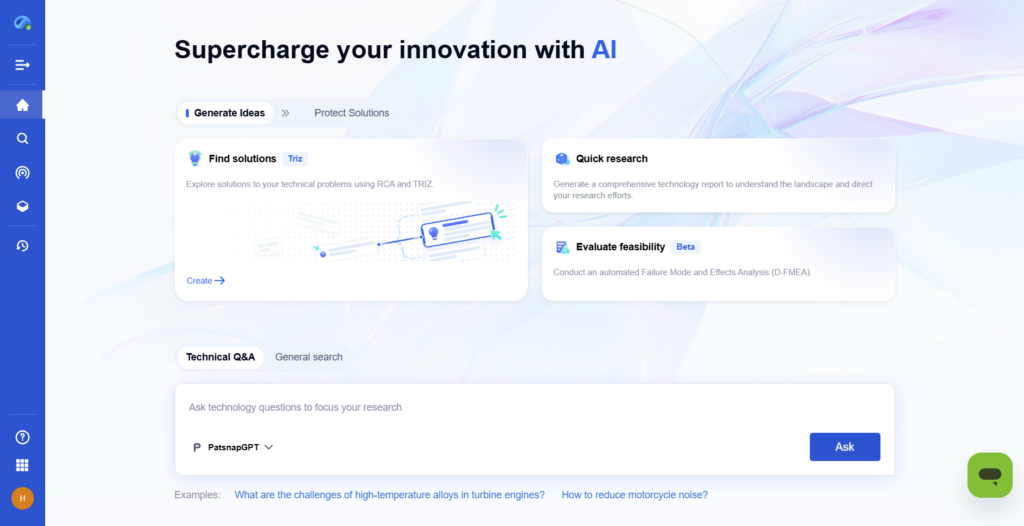

How Eureka Enhances Calcium Stearate Research and Innovation

Eureka by PatSnap is an AI-powered innovation intelligence platform that helps R&D teams accelerate discovery, monitor emerging trends, and stay ahead of the competition—especially in fields like material science and chemical formulation.

- Patent Landscape Analysis: Eureka identifies the latest patents related to calcium stearate applications, such as stabilizers in PVC, food-grade lubricants, and pharmaceutical excipients.

- Emerging Market Insights: The platform detects growth areas in industries using calcium stearate, helping researchers explore new opportunities in biodegradable plastics, coatings, and agricultural formulations.

- Competitive Intelligence: Eureka helps manufacturers benchmark against top competitors by analyzing their R&D focus and formulation strategies involving this compound.

- Trend Forecasting: Using AI-based clustering, Eureka visualizes global innovation trends in calcium-based additives, allowing companies to align their product development with future demands.

If you’re in materials science, plastics engineering, or pharmaceutical manufacturing, Eureka empowers your team to make smarter, faster, and data-driven innovation decisions involving calcium stearate.

FAQs

Is calcium stearate safe to eat?

Yes, regulatory agencies allow its use as a food additive in small amounts, mainly as an anti-caking agent.

What is its role in concrete?

It makes concrete water-repellent, which increases durability and prevents salt deposits on the surface.

Can you use it in cosmetics?

Absolutely. It improves powder flow, provides texture, and prevents caking in makeup products.

Is calcium stearate natural or synthetic?

Although derived from natural stearic acid, it is synthetically processed for industrial consistency.

Does it dissolve in water?

No. Its insolubility in water allows it to act as a moisture barrier in many formulations.

Conclusion

Calcium stearate is a versatile and essential compound in industries ranging from construction to cosmetics. Thanks to its stability, lubricity, and non-toxic profile, it serves as a valuable additive in countless applications. Whether enhancing the flow of tablets or increasing the water resistance of concrete, calcium stearate proves itself time and again as a reliable solution. As the demand for safe and functional additives grows, this compound remains an industry favorite for its cost-efficiency, versatility, and performance across multiple sectors.ompound across both industrial and consumer sectors.

To get detailed scientific explanations of Calcium Stearate, try Patsnap Eureka.