What is an AC Condenser?

An AC condenser, or air-cooled condenser, plays a vital role in air conditioning systems. It condenses refrigerant from gas to liquid by transferring heat to the surrounding air. This process is crucial for the refrigeration cycle. This article will explore how AC condensers work, their components, and maintenance tips to keep them running efficiently.

How Does an AC Condenser Work?

Function and Principle

The condenser dissipates the heat absorbed by the refrigerant from the evaporator. It works by converting high-pressure gas into liquid, releasing heat to the surrounding air. The system includes the condenser coil, fan, and refrigerant connections to the compressor, expansion valve, and evaporator.

Components and Operation

Compressor: It raises the refrigerant’s temperature and pressure before sending it to the condenser.

Condenser Coil: Here, hot refrigerant gas releases heat and turns into liquid as it flows through the coil.

Fan: The fan boosts heat transfer by blowing air over the condenser coils, improving efficiency.

The liquid refrigerant then moves through an expansion valve, reduces pressure, and becomes cold. It travels to the evaporator, absorbs heat, and the cycle repeats.

AC Condenser vs. Evaporator Coil: Key Differences

Function and Principle

Condenser Coil:

The condenser coil releases heat from the refrigerant, turning it from gas to liquid. It’s usually located outside and made of copper tubes with aluminum fins to boost heat transfer. A fan circulates air across the coil to help dissipate the heat.

Evaporator Coil:

The evaporator coil absorbs heat from the indoor air, causing the refrigerant to evaporate into a gas. It’s typically located inside the building in the air handler or furnace. Air blows over the coil, and the refrigerant absorbs heat, changing from liquid to gas.

Components and Structure

Condenser Coil:

The coil has tubing for refrigerant flow and fins for heat transfer. It may use materials like copper or aluminum alloys for the tubes and fins. A fan is often included to increase airflow.

Evaporator Coil:

Like the condenser, it features tubing for refrigerant flow and fins for heat transfer. It may also include components like suction pressure control valves. The design maximizes heat exchange between the refrigerant and indoor air.

Operating Conditions

Condenser Coil:

The coil works in hot outdoor conditions, where the temperature difference between the refrigerant and the air is significant. Proper airflow is necessary for efficient heat dissipation.

Evaporator Coil:

This coil operates in cooler indoor environments, aiming to maintain a comfortable temperature. It also helps control humidity by condensing water vapor from the air.

Performance and Efficiency

Condenser Coil:

Optimizing the fin design, tube material, and airflow improves efficiency. Features like porous inserts or vortex generators can enhance heat transfer.

Evaporator Coil:

Factors like refrigerant flow, air circulation, and coil design affect performance. Regular cleaning is crucial to maintain efficiency and prevent buildup.

Signs Your AC Condenser Needs Repair

- Reduced Airflow: If you notice reduced airflow from your vents, dirty or obstructed coils could be limiting airflow and efficiency.

- Increased Energy Bills: Higher-than-usual energy bills may indicate the system is working harder due to inefficient cooling.

- Unusual Noises: Strange noises like hissing, clanking, or grinding could point to issues with refrigerant, coils, or other components.

- Warm Air: If the air feels warmer than usual, it may signal poor cooling due to dirty coils or a refrigerant leak.

- Ice Buildup: Excess ice on the coils suggests the system can’t release heat properly, often due to low refrigerant.

- Foul Odors: A musty smell from the vents could mean mold or bacteria growth, often caused by dirty coils.

- Visible Damage: Physical damage, such as dents, rust, or broken parts, can reduce efficiency and overall system performance.

- Increased Humidity: If the air feels too humid, it may indicate that moisture isn’t being properly removed from the air.

AC Condenser Troubleshooting Tips

Fouling and Dirty Coils:

Over time, dirt, dust, and debris can build up on coils, restricting airflow and heat transfer. Regular cleaning is key to keeping performance up.

Low Refrigerant Charge:

A low refrigerant level hampers heat dissipation, lowering system efficiency. Leaks should be fixed quickly to restore proper performance.

Fan Problems:

The fan is essential for heat dissipation. Malfunctions, incorrect fan speed, or blockages can significantly hurt efficiency. Regular fan checks are important.

High Ambient Temperatures:

Extreme outdoor temperatures strain the system, reducing efficiency. Ensure proper clearance around the unit and consider high-efficiency models to minimize impact.

Applications of AC Condenser

Power Generation:

In power plants, condensers help condense low-pressure waste steam from turbines in a Rankine cycle. They’re especially useful in water-scarce regions due to their low water consumption compared to wet-cooling systems.

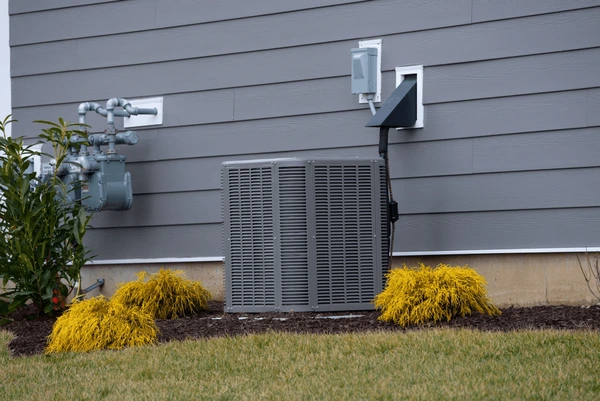

Air Conditioning Systems:

Condensers dissipate heat from refrigerants in both residential and commercial air conditioners. You’ll find them in household refrigerators, industrial freezers, and window air conditioners.

Refrigeration Plants:

Condensers are key in refrigeration plants, where they condense refrigerant vapors like ammonia or fluorinated hydrocarbons, maintaining cycle efficiency.

Automotive Industry:

In vehicles, condensers help condense refrigerants in air conditioning systems, ensuring passenger comfort. They work efficiently even when the vehicle is stationary.

Industrial Applications:

Condensers play an important role in chemical engineering, water desalination, and energy conversion, known for their durability and low maintenance needs.

HVACR Systems:

In HVACR systems, condensers regulate temperature and air quality by providing ventilation and air filtration.

Specialized Systems:

Specialized systems, like car air conditioners using chlorofluorocarbon refrigerants, also rely on condensers for precise temperature control.

Application Cases

| Product/Project | Technical Outcomes | Application Scenarios |

|---|---|---|

| Real-time Air-Cooled Condenser Monitoring Platform | Developed a surrogate model using thermofluid simulation data, achieving 99.85% classification accuracy and reducing compute time significantly. | Power plants requiring real-time performance predictions for air-cooled condenser systems. |

| Air-Cooled Condenser with Deflection Limiter Beams Holtec International, Inc. | Prevents out of plane tube bowing by providing a guided restraint system for expansion/contraction of tube bundles. | Steam condensing applications in power plant Rankine cycles. |

| Condenser Assemblies for HVACR Systems Hobart Brothers LLC | Improves efficiency and reduces the need for system shutdowns, enhancing productivity. | Heating, ventilation, air conditioning, and refrigeration systems. |

| Condenser MAHLE International GmbH | Reduces space consumption and facilitates gas-liquid separation. | Air conditioning systems, particularly in motor vehicles. |

| Condenser for Air Conditioner Valeo Klimasysteme GmbH | Optimizes flow canal design to improve coolant flow and efficiency. | Air conditioning systems in motor vehicles. |

Latest Technical Innovations in AC Condenser

Eco-friendly Designs:

Innovations like evapo-transpiration condensers improve efficiency and reduce waste heat, potentially saving up to 30% of energy in summer.

Material and Design Optimization:

Research focuses on enhancing heat transfer by optimizing materials and designs, leading to more efficient systems.

AI and IoT Integration:

Integrating AI and IoT enables real-time monitoring and predictive analytics, improving troubleshooting and overall system efficiency.

To get detailed scientific explanations of AC condensers, try Patsnap Eureka.